Table of Contents

iQ-Analyzer-X V1.11.1 Manual

This is the original, not translated, manual. It will be updated with every release of iQ-Analyzer-X. If you need to save the current version for some reason, please use the “Export to PDF” button. If you find anything missing or have suggestions, please let us know (support@image-engineering.de). We are happy to help!

The software is linked to this online manual. Click on “Online Help” and move the mouse pointer over the graphical user interface.

When you hover over a linked section, a question mark appears on your mouse pointer. Click on the section to go to the corresponding section in this online manual.

Please read the section Important Information about Test Charts to check, if special actions are required for the test chart applied!

What’s new in iQ-Analyzer-X?

The iQ-Analyzer-X is an all-new development. The most significant changes are:

- Increased overall speed (start-up time, detection times, etc.) due to the C++ implementation

- A versatile and customizable user interface

- Automatic chart detection and custom chart support

- Database storage for storing and accessing all previous results

- Custom workflows for managing unique evaluation specifications

- Side-by-side comparison of analysis results

System Requirements

The iQ-Analyzer-X is compatible with Windows 10 and 11.

Windows 11 on ARM (Apple) is also supported.

Limitation:

The automated chart classification depends on hardware-accelerated GPU support.

If this is not available on the PC, the chart classification is disabled.

As you might work with large image data files, please consider a PC with reasonable performance standards.

The iQ-Analyzer-X uses the industry-standard OpenGL for some 3D plots. Please be aware that such plots are not visible if the graphics board of your PC does not support OpenGL.

UTT users only: To import UTT reference files (.xlsx) to the iQ-Analyzer-X database, you need an installation of MS Excel or MS Office on the PC.

Licensing

The latest release of iQ-Analyzer-X is available to download on the Image Engineering homepage. If no dongle is attached to your computer, iQ-Analyzer-X runs as the Free Version with limited functionality. With an active license (via USB Dongle), the software will start as the Pro Version. If you have an active maintenance package, you can use all updates released within your maintenance period.

Free Version

- Compatible with all iQ-Analyzer-X test charts

- Install on unlimited devices

- Configurable user interface

- Analysis templates

- Analyze RAW files

- Configurable test result tables

- Zoom function of the image

Use individual reference dataSave results to a databaseExport results as XML or PDFMaintenance Package and Priority Support

Cultural Heritage Version

- Compatible only with UTT and Color test charts

- Install on unlimited devices

- Configurable user interface

Analysis templatesAnalyze RAW files- Configurable test result tables

- Zoom function of the image

- Use individual reference data

- Save results to a database

- Export results as XML or PDF

- Maintenance Package and Priority Support

Pro Version

- Install on unlimited devices

- Configurable user interface

- Analysis templates

- Analyze RAW files

- Configurable test result tables

- Zoom function of the image

- Use individual reference data

- Save results to a database

- Export results as XML or PDF

- Maintenance Package and Priority Support

Installation and Database Setup

To install iQ-Analyzer-X, click on the executable and follow the instructions. If you launch iQ-Analyzer-X for the first time, a local database will initialize for your analysis results. The progress of initialization is displayed in a progress bar.

Software updates are installed separately in their own folder. We recommend that you back up your database before updating the software, just in case something goes wrong. How to create a backup is explained in the “Database” section.

Note, that if you are considering using Open Database Connectivity (ODCB) in the future, you can use the “Database Migration Tool” to transfer the analysis data from a local to a remote server database. A migration from one to another remote database is also possible. The database migration tool can be started from the “Help” menu. It is explained in its own chapter.

Open Database Connectivity (ODBC)

iQ-Analyzer-X provides an interface for ODBC, enabling you to run a database on a remote server accessible from multiple PCs in different locations. To use ODBC, you need to create a database on your SQL server first. We have verified that MySQL, MSSQL, and MariaDB work well with the ODBC connectivity of iQ-Analyzer-X. Once you have created the database, you need to install the corresponding driver on your operating system. With the Windows “ODBC Datasources” tool, you need to set up the connection to the remote database. Note, that for MSSQL it is required, that the database you want to use is set as the default database in the database driver as well. If it isn't set, connection issues might occur.

After successfully connecting to the remote database, start the iQ-Analyzer-X and open the “Configuration” dialog. In the “General” tab is a section for the database configuration. Activate the “ODBC database” option. Now the dropdown menu for “Database name” is accessible. Choose the database you created from the dropdown menu. The database tries to establish a connection immediately and asks for your credentials. If it's the first time you connect to the database, you are asked to provide a “Network shared image folder” where all images are saved permanently. The folder can be changed any time in the settings. Also, you need to click on “Initialize database” to once set up the tables in the database. If everything worked correctly, the database status shows a green check symbol, and you are ready to use your database.

You can navigate to the “ODBC Data Sources” dialog by pressing “Configure Databases”.

Dongle

The USB dongle needs to be attached to your system to access the full functionality of iQ-Analyzer-X. The dongle keeps the information about your maintenance period, and the software shows a message before this period expires. Please contact our sales team if you want to extend the maintenance.

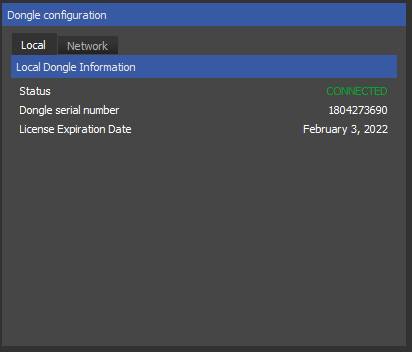

You can find general information about your dongle in the “General” tab under “Configure.”

Network License

A USB Dongle needs to be connected to the PC to run the iQ-Analyzer-X Pro Version. Since version 1.4, iQ-Analyzer-X also provides a network license feature. The USB dongle can be attached to a server, and the local PC does not need to have physical access to the dongle. With one USB dongle, you can have multiple concurrent with the network license. The management of the simultaneously running versions of iQ-Analyzer-X is performed with the help of user slots in a server file generated by the “MATRIX-Net” server program from “TechnoData Interware GmbH.”

The MATRIX-Net functional principle is shown in the diagram above. The server program running on a computer with the dongle generates an encoded server file. Each running version of the iQ-Analyzer-X “connects” with the server file and occupies a user slot released when the application is closed. The network protection via MATRIX-Net does not use network protocols and can thus be used in any network system.

Installation of the Network License

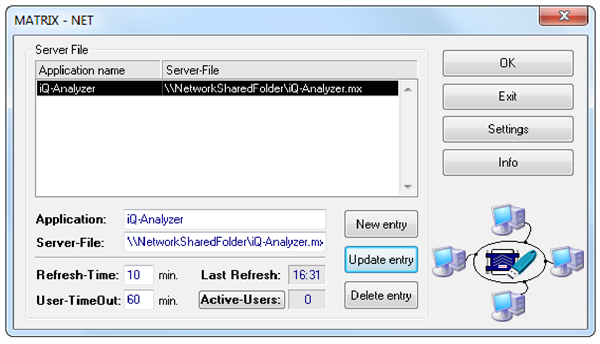

When installing the network license, you need the mxnet32.exe, which is located in the installation directory of your iQ-Analyzer-X version under “NetworkLicenseTool.” Connect the dongle to your dedicated server and run mxnet32.exe. This process opens the MATRIX-NET program (the MxNet server application) and must run on the server PC.

The MxNet server program can also be registered as a Windows service so that the program is started automatically during the boot-up of Windows. The advantage of a service over an Autostart entry is the ability to start even if there is no User-Login in Windows. You can directly register MxNet as a service by starting MxNet with the corresponding parameters. The following call-up parameters are available: mxnet32.exe -i (Install MxNET service) and mxnet32.exe -r (Uninstall MxNET service).

After starting the MATRIX-NET program, a dongle symbol is displayed in the taskbar.

Clicking on this icon opens the MATRIX-NET dialog.

Create a new entry in the Server file list. Enter a name for the program in the field “Application name.” The name can be anything you like, and it does not need to match the actual application name. The network licenses are managed using a .mx server file. You can create the server file yourself and enter its path under “Server-File,” or you can enter a full path with a .mx file and click “New Entry.” The file is then automatically generated. The name of the server file must always be entered with the absolute path and correspond to the naming conventions of the operating system.

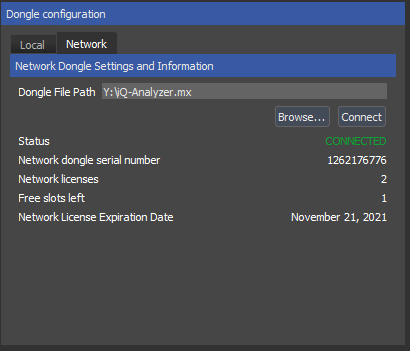

After setting up and running the MATRIX-NET server, install iQ-Analyzer-X on the client PCs. On each computer, you need to enter the server file you just created in the “Dongle File Path” field in the “General” tab under “Configure.” You can also browse for the file. After providing the path, click connect. If the connection was successful, the status is shown in green as “CONNECTED.”

The “Network” tab shows information about the dongle, the total number of licenses, and the free slots.

MATRIX-NET Settings

REFRESH-TIME

In this field, the time interval for the refresh of the server file is set. The last refresh carried out is displayed in the “Last Refresh” field. The refresh period should usually be selected to be between 5 and 10 minutes.

USER-TIMEOUT

The User-TimeOut is the time limit after which the user is automatically removed from the server file. In the event of abnormal termination of the application (crash) on a client, this function ensures the release of the user slot in the server file, as this would otherwise remain occupied.

ACTIVE-USERS

This field is continuously updated and shows the total number of active users for the selected application. The “Active-Users” button allows you to display a detailed list of the active users. A user entry can be manually removed from this list. If your application is terminated abnormally on any terminal, you can either remove the user slot from the list or wait for the time out. When the user time out is reached, the user slot is automatically removed when the server file is refreshed. It is unnecessary to delete the user slot before the abnormally terminated application is restarted. The existing user slot will be found and refreshed automatically.

Important! Important! It is essential that the system time of the PC is synchronized in the network; otherwise, the “User-TimeOut” can not be correctly computed. The maximum allowed deviation of the system time between clients and server may not exceed the number of minutes selected in the MATRIX-NET server program in “Refresh-Time.” The following command can synchronize the clients’ system time with the server’s system time. This command can be implemented in the boot-up procedure of each client to make it an automatic function.

NET TIME \\<computername> /SET /YES

Getting started

This is a quick guide on how to run your first analysis in iQ-Analyzer-X Pro. If you use the CH Version, please refer to chapter “UTT”. Example images are provided on the iQ-Analyzer-X download page.

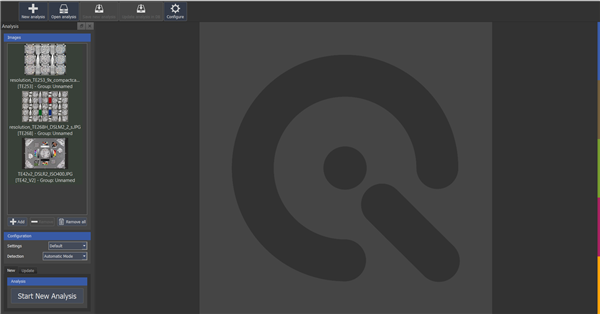

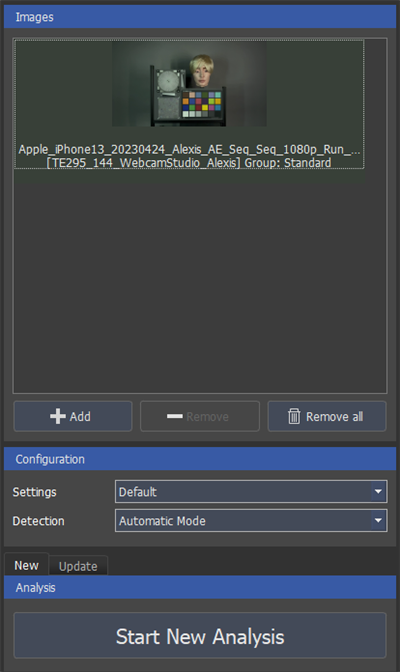

The first time you launch iQ-Analyzer-X it, takes a moment to initialize the local database in which the future analysis will be saved. After the initialization is done, click on “New Analysis.”

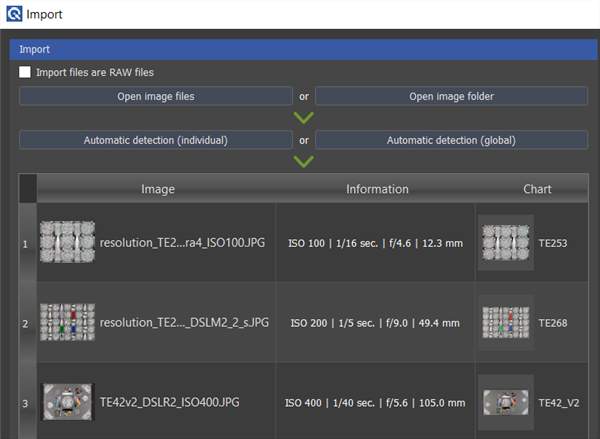

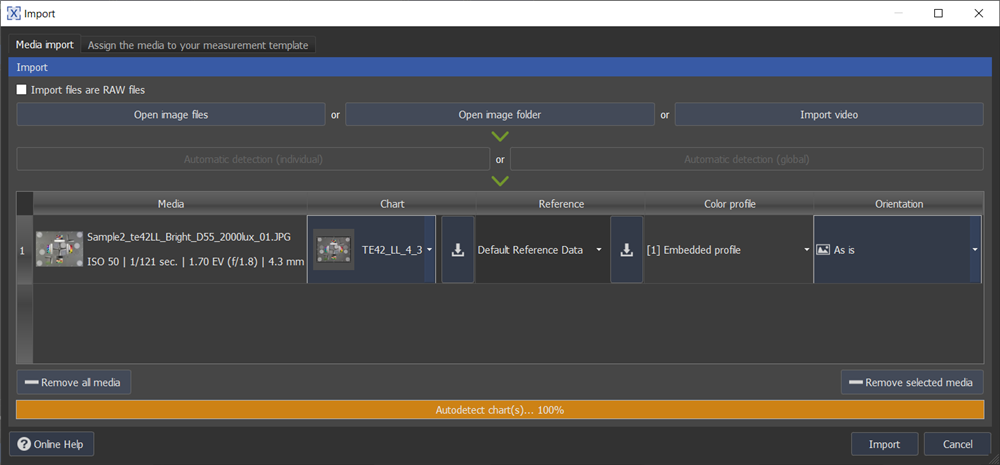

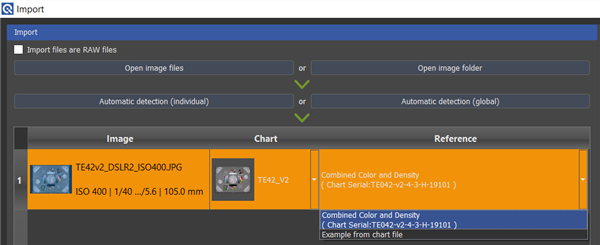

The “Import Images” dialog will appear. You can either load single images with “Open Image Files” or all the images in a folder with “Open Image Folder.” For now, please open a single image. The software detects the test chart automatically and shows it in the “Chart” column. If there are problems with the automatic detection, the chart can also be selected manually with the dropdown menu in the “Chart” column.

If all charts are detected, click “Import.” The main window will appear with the “Input“ dock showing the imported images.

Apply your desired settings and the detection mode under “Configuration.” For your first analysis, the default values will be adequate. Click on “Start New Analysis” to launch the first image analysis. The results will be presented in the “Analysis results” tab when the analysis is completed. Switch through the different tabs to see the visualization of your measurements. You can also undock the tab from its container for a better view.

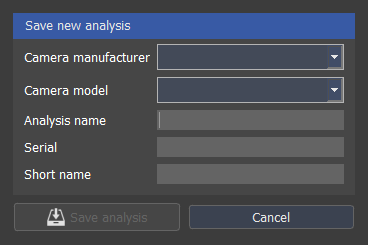

To save your analysis, click on “Save new analysis.”

Enter the details of your analysis and click on “Save Analysis.” A good description will help you find your analysis more quickly in the database.

Congratulations! You just performed your first image quality analysis with iQ-Analyzer-X.

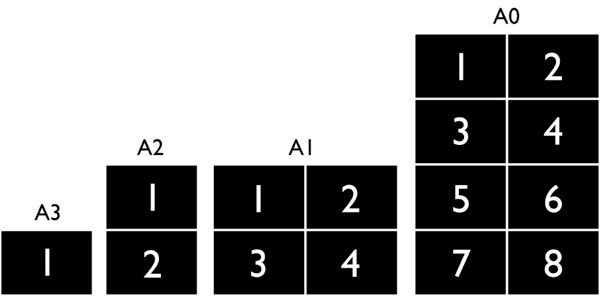

Important Information for Test Charts

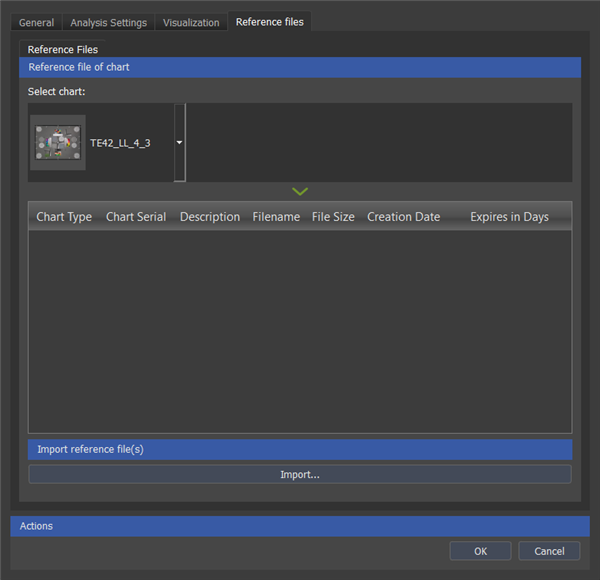

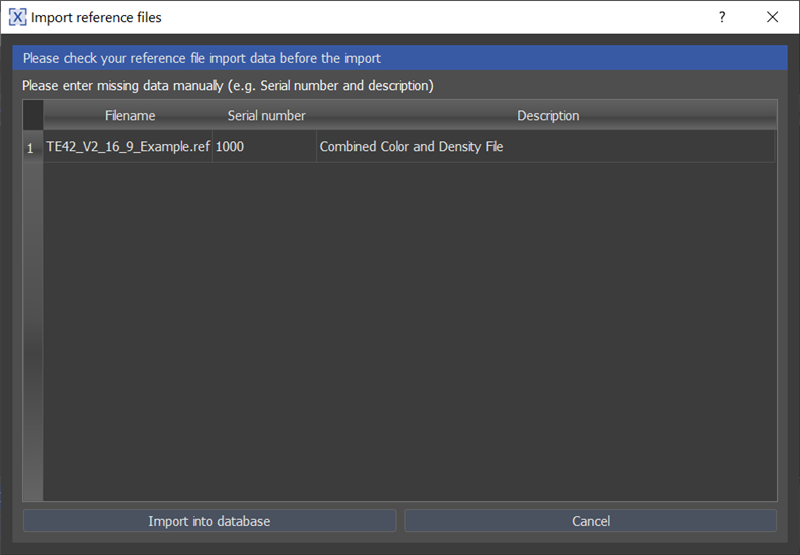

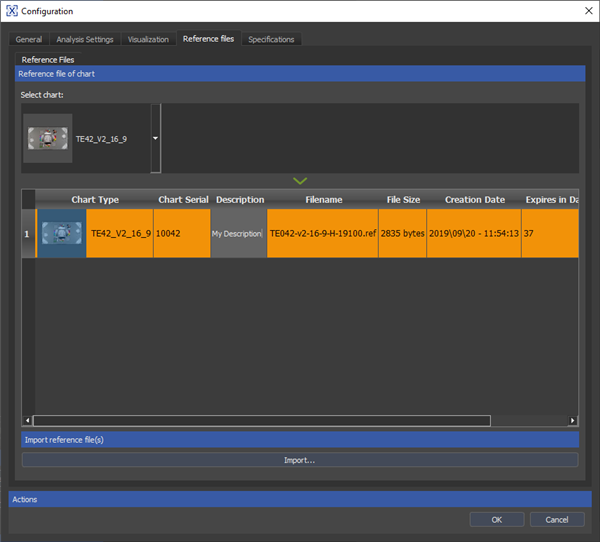

Please check this list before working with your test chart. For most charts, we recommend to work with the individual reference file. Please refer to the chapter Reference Files for more information.

| Chart | comment |

|---|---|

| TE42LL 2AR | The chart comes with two reference files for the two different aspect ratios 4:3 and 16:9 which can be analyzed. Please assign the according .ref file in the “Import” dialog. |

| TE42LL | Only the corner and center Siemens Stars are analysed. |

| TE165 | Only the top row OECF patches are analyzed |

| TE188 | The default reference data is for reflective charts only. If your chart is transparent, it's required to import the individual reference file first, if available. |

| TE240 | The software only detects the chart, but not its variant (1:10.000 or 1:1.000.000). The default reference data is for a contrast of 1:10.000. If the contrast of your chart is 1:1.000.000 you need to create a reference file first! Please assign the correct reference data in the import dialog. |

| TE259 | Only the top row OECF patches are analyzed |

| All TE268 | From the slanted edges, only eight in the center are analyzed |

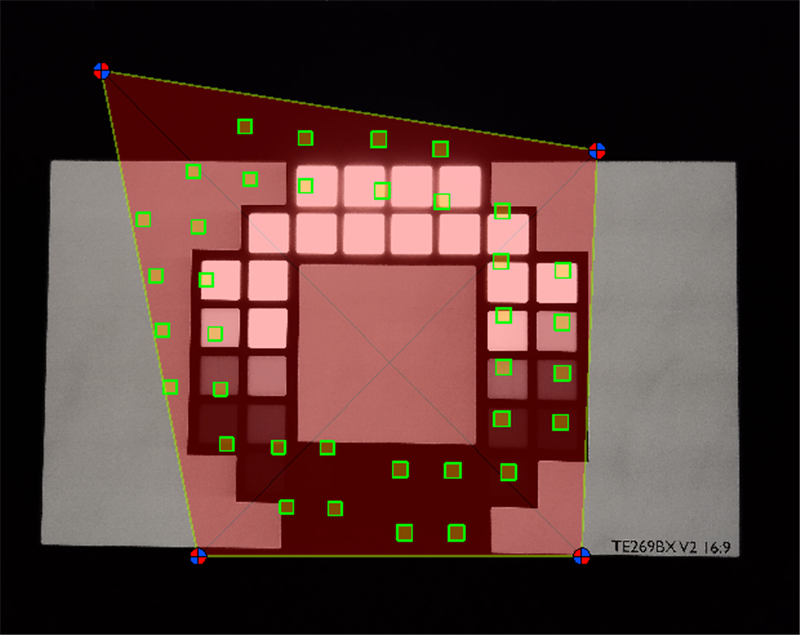

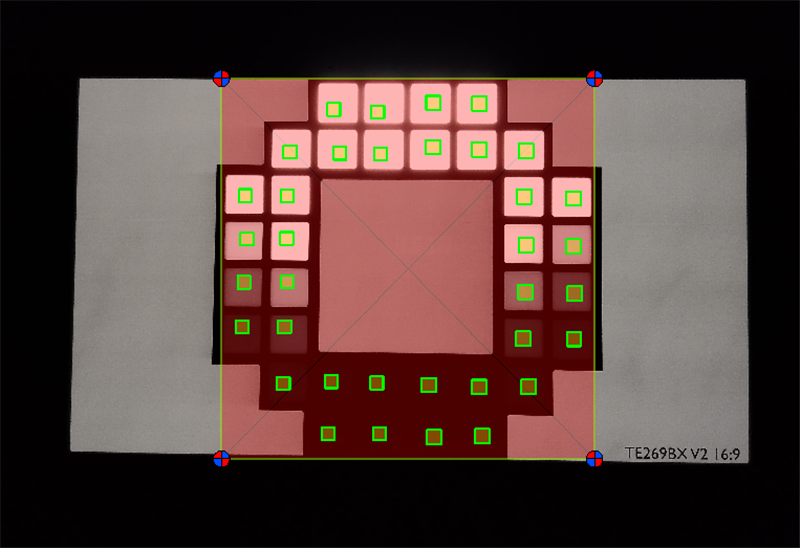

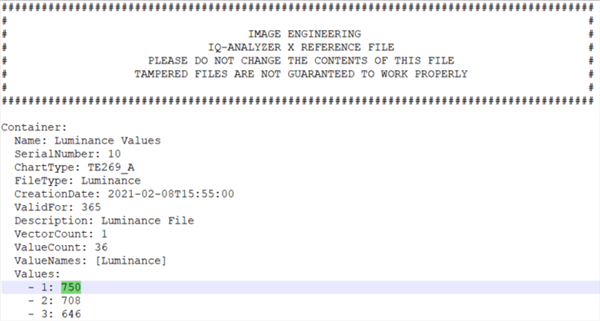

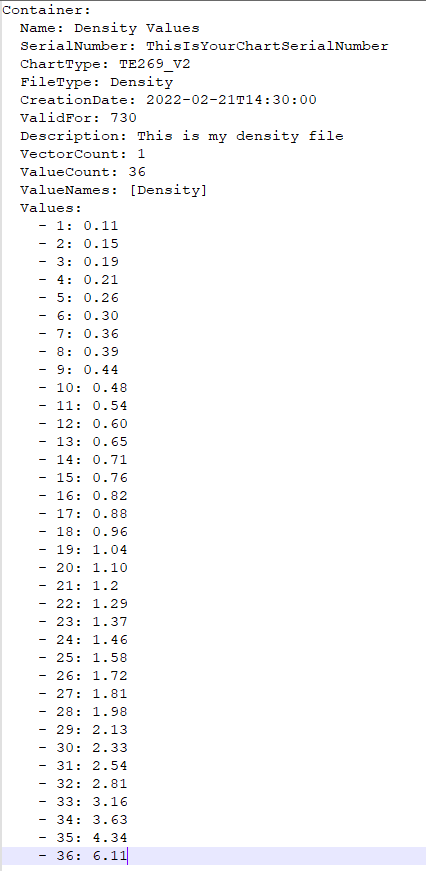

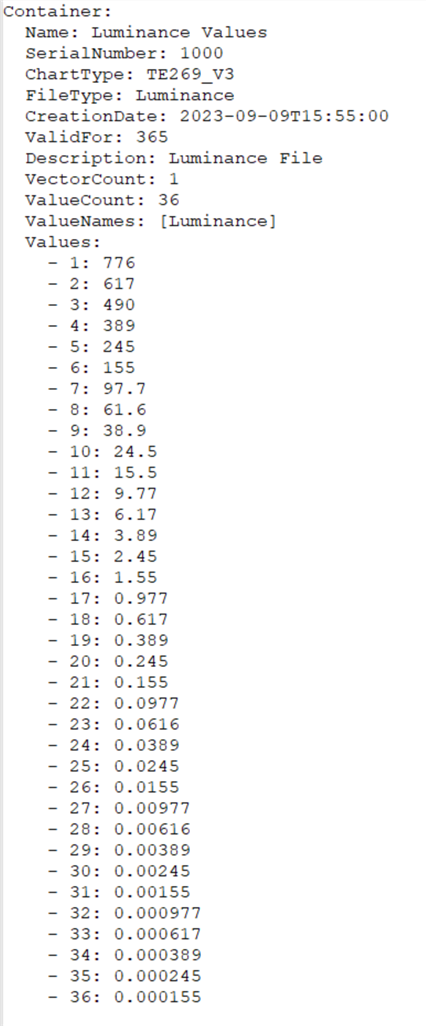

| All TE269 | The software only detects the chart, but not its variant ( A, B or C ). Please import and assign your individual reference file to avoid confusion. If you do not have an individual reference file, you need to import the default reference data of your chart first. The default reference files are located in C:\Program Files\Image Engineering\iQ-Analyzer-X X.X.X\resources\references\templates. How to import reference files is explained in chapter "reference files". |

| All TE264 | The software only detects the chart, but not its variant ( 10000:1 or 1000000:1 ). Please import and assign your individual reference file to avoid confusion. |

| TE296 | The chart is available in two contrasts, 4:1 and 6:1. A contrast of 4:1 corresponds to a modulation of 60% and 6:1 corresponds to approximately 70%. The graphs therefore show mod 60/70 in the legend. |

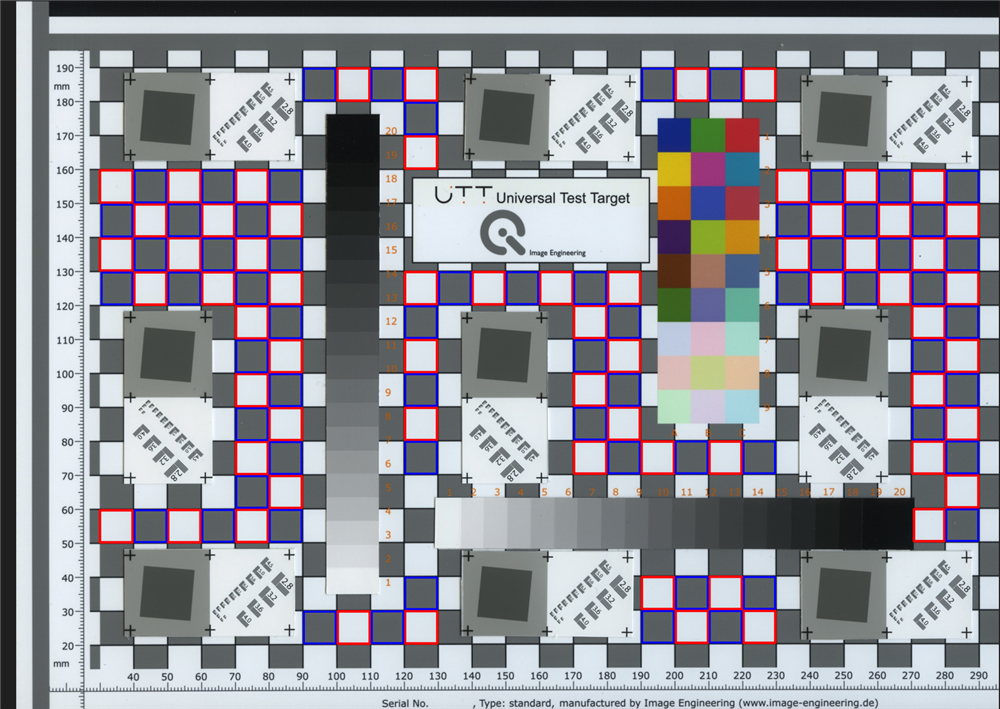

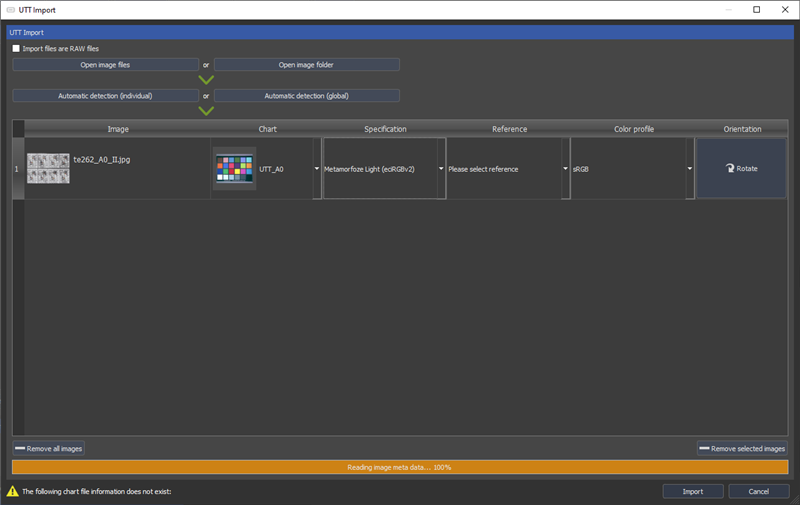

| All UTT Charts | An Excel Version needs to be installed to import individual reference files |

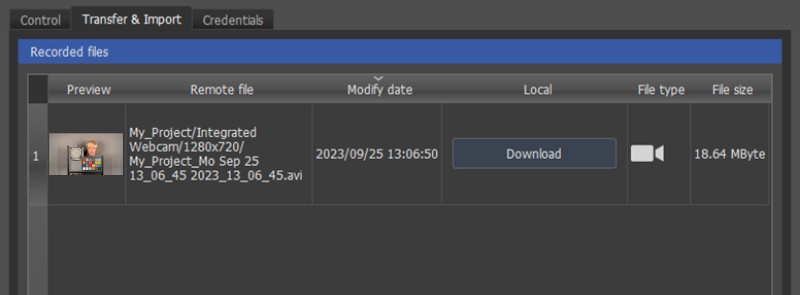

| iQ-Analyzer-X currently does not recognize the chart layout of the UTT (A0, A1, A2, A3 or A4) automatically. This means you need to assign the layout manually before analysis in the import dialog. A wrong allocation might lead to a crash. |

Image Quality Analysis

General Workflow

The iQ-Analyzer-X detects the type of test chart automatically and provides the results accordingly. The basic concept requires that each analysis is only for one specific device make and model. The analysis will be stored in a database, and several results of different cameras can be opened simultaneously for comparison. All necessary analysis settings are in one place, and you can create custom settings and store them in the database.

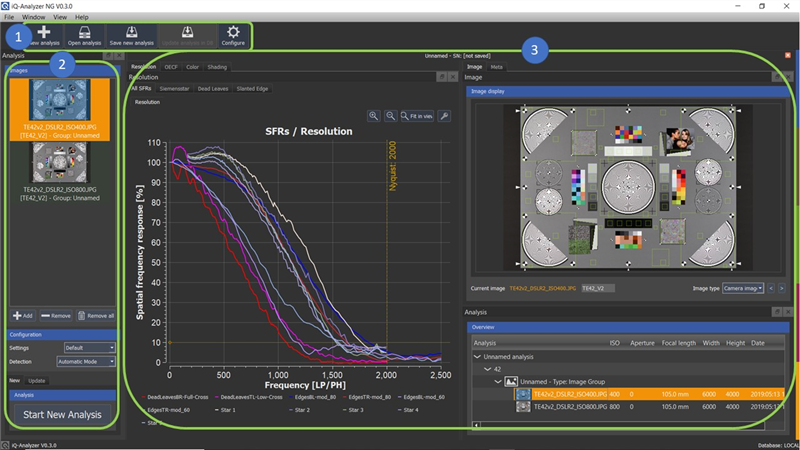

GUI Overview

The GUI consists of several docks and windows that can be individually placed on your screen by drag and drop. To change the position of a window, click into the top row and drag it to your desired position. If you drag it onto another window, it will show appear as a tab.

It is also possible to pin or unpin some of the sections by clicking on the small pin in the top right. An unpinned section will always be visible.

A pinned section appears as a symbol and can be unfolded by clicking on it. You can use this feature to get more working space.

You can always go back to the original state by selecting “restore view to default” in the “view” menu. Most result graphs and image overviews can be zoomed in and out with the mouse wheel or move positions with click and drag.

In the default view after an analysis, the GUI shows the “Toolbar” dock (1), the “Input” dock (2) (pinned), and the “Analysis Results” tab (3). The “Toolbar” provides a shortcut to a few basic functions. The “Input” dock shows all imported images and lets you define the settings for your image analysis. The “Analysis Results” tab contains all the results and information about the currently active test image. The currently active image is highlighted in orange.

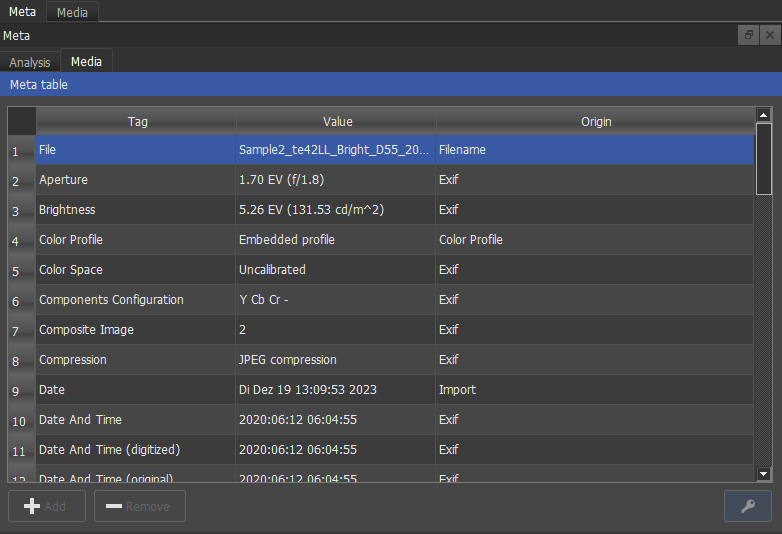

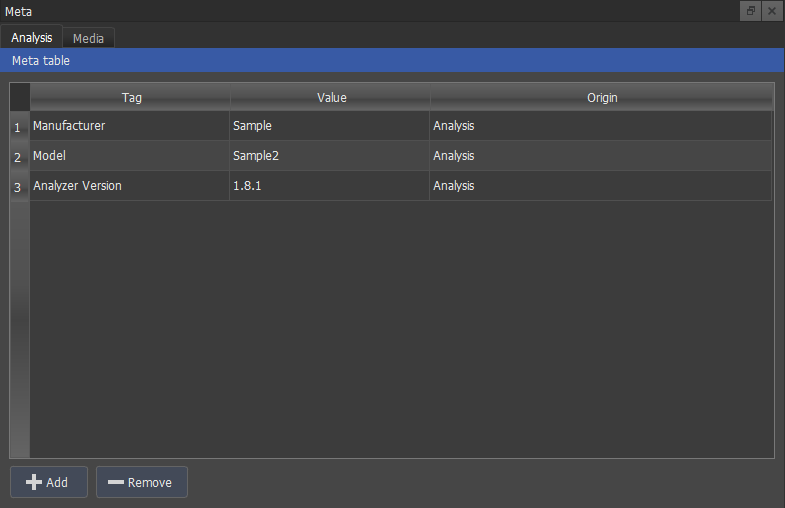

Meta Tab

The meta information of the currently active image under test and analysis is displayed here. How to change the metadata is explained in a later chapter.

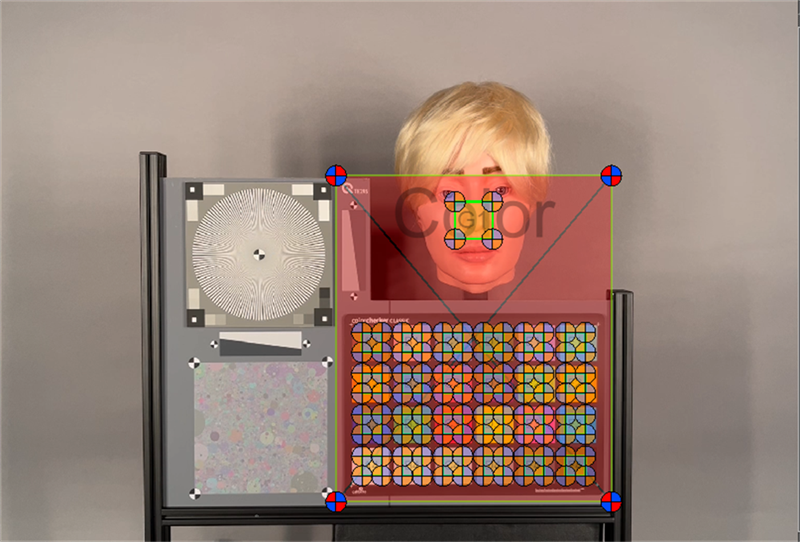

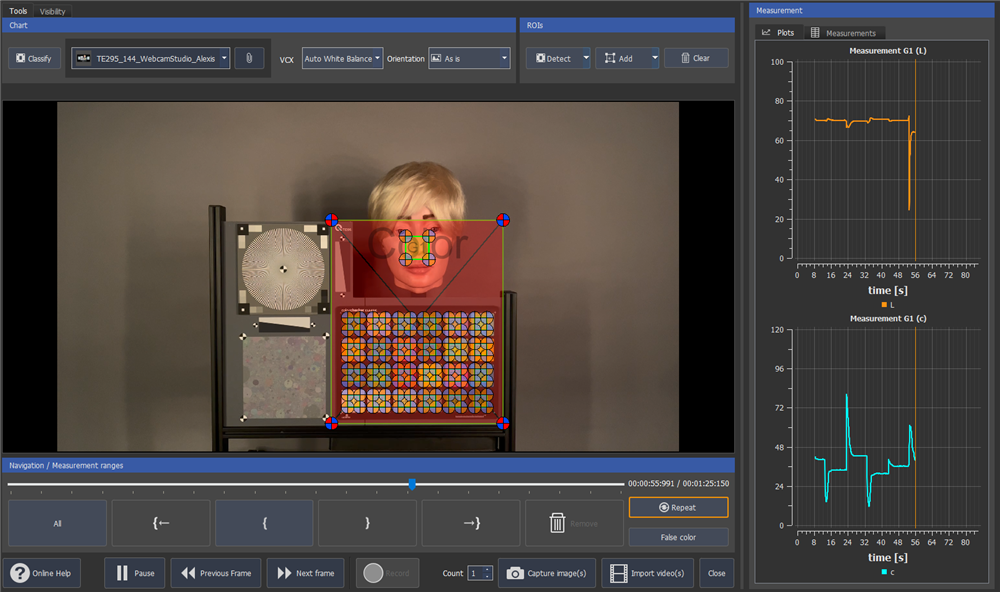

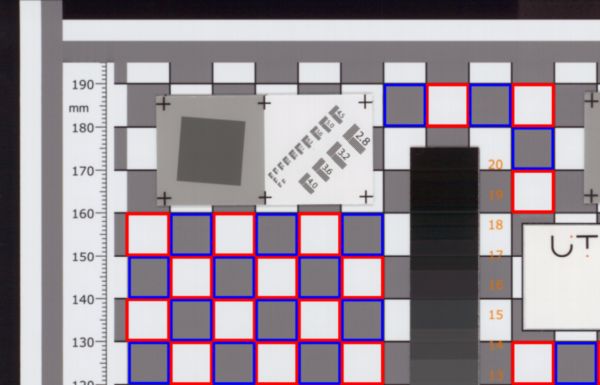

Media Tab

The current active test image or video with all ROIs detected is displayed here. This view is beneficial to check if the ROIs are in the correct location or any artifacts like reflections. It also highlights the corresponding targets when you hover over a line in its results plot. This feature makes it easy to see the target's connection and result. You can easily zoom in and out by using your mouse wheel, and the zoom will focus on the location of the pointer of your mouse.

Hover over the buttons below the viewer to see their functions.

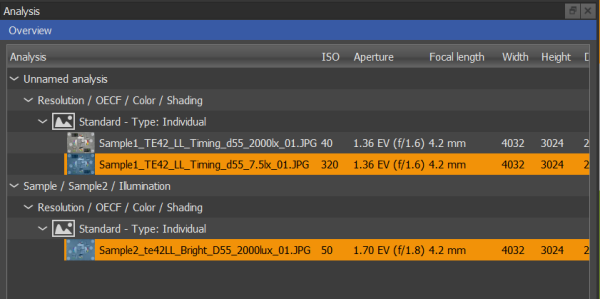

Analysis Tab

This tab provides an overview of the images in your active analysis. If multiple analyses are open, the active analysis is the one with the highlighted text in the headline of its tab. The overview provides a simple way to switch between the test images or to show the results of multiple selected images combined in one plot and table.

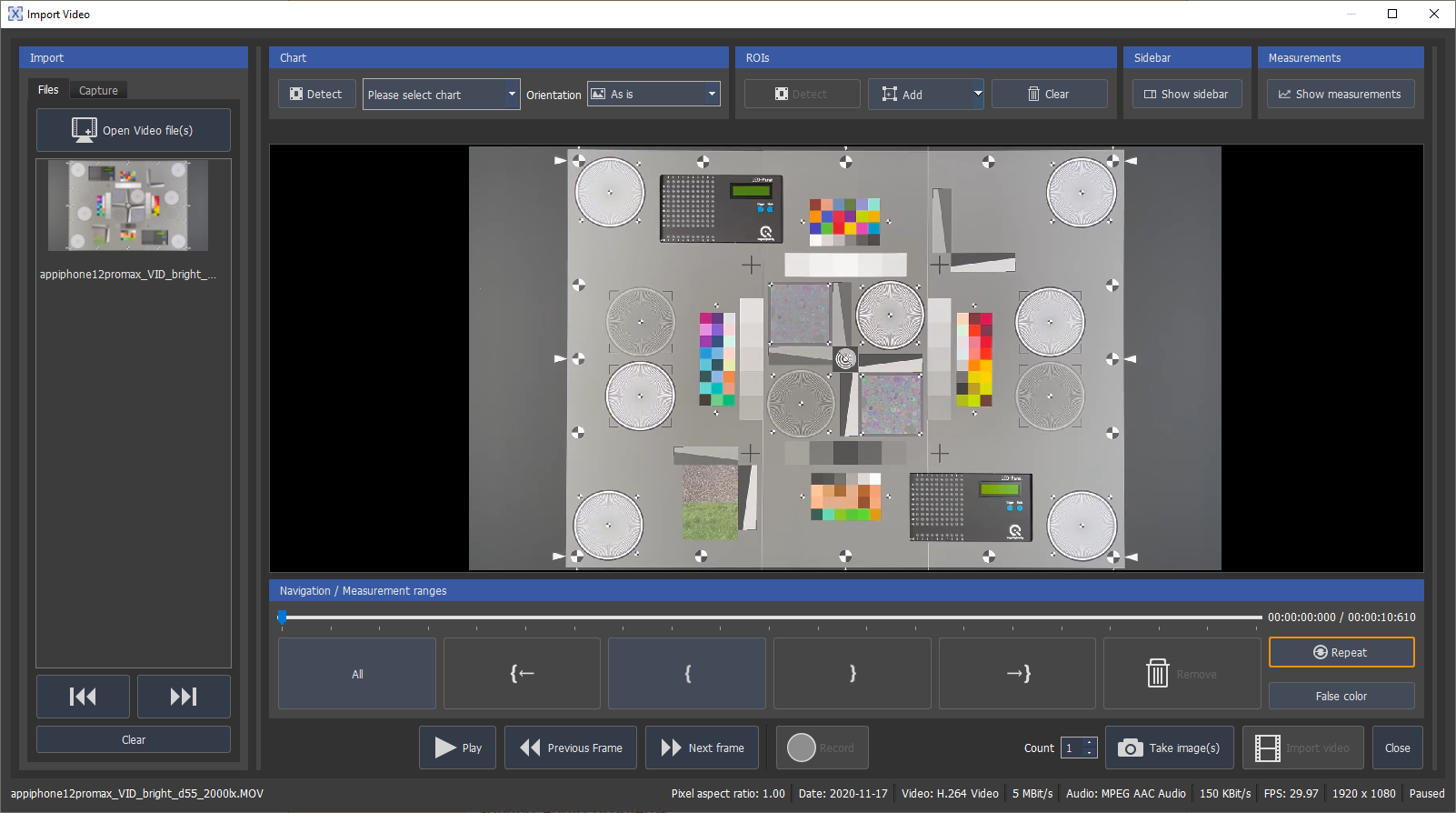

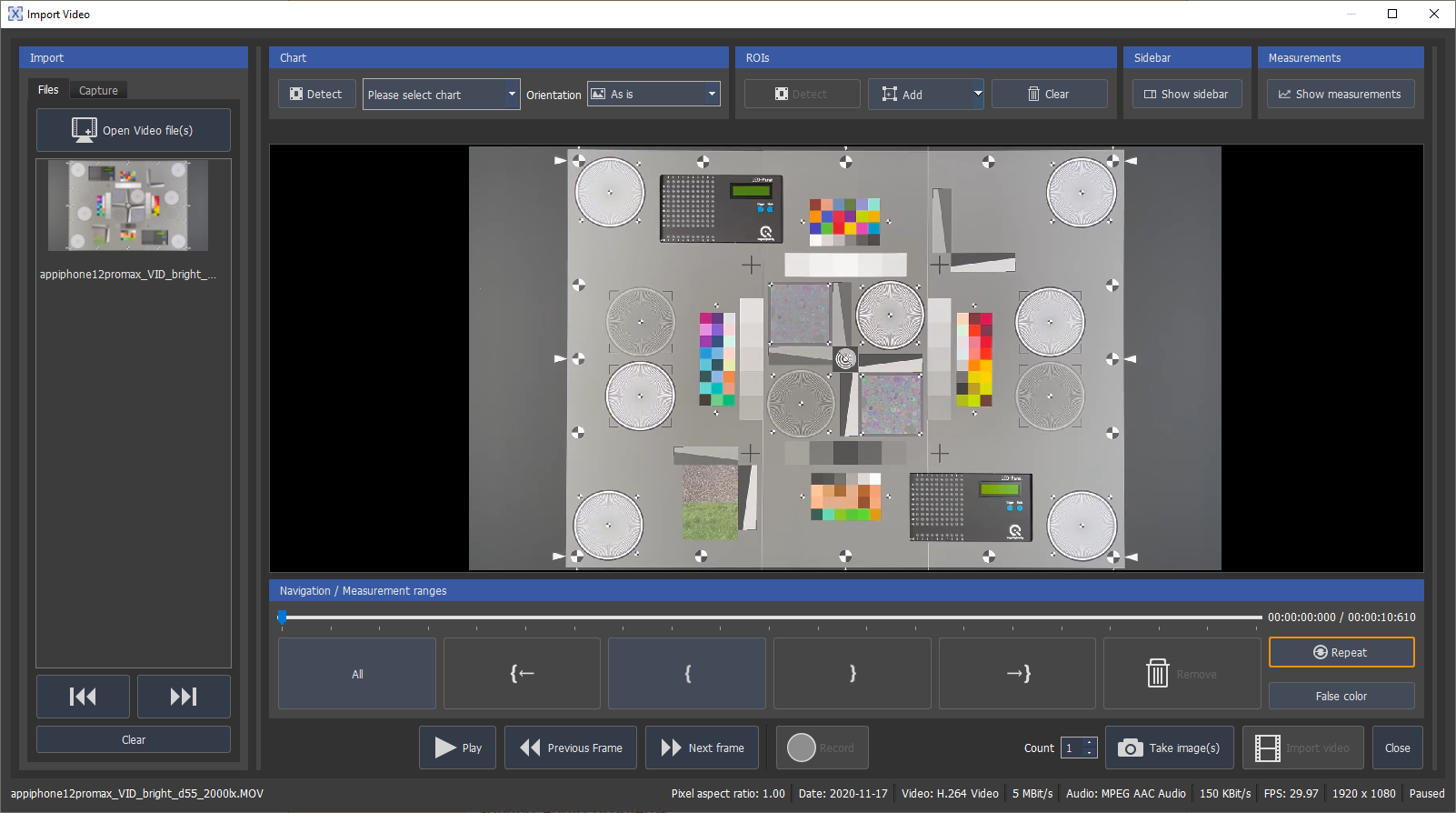

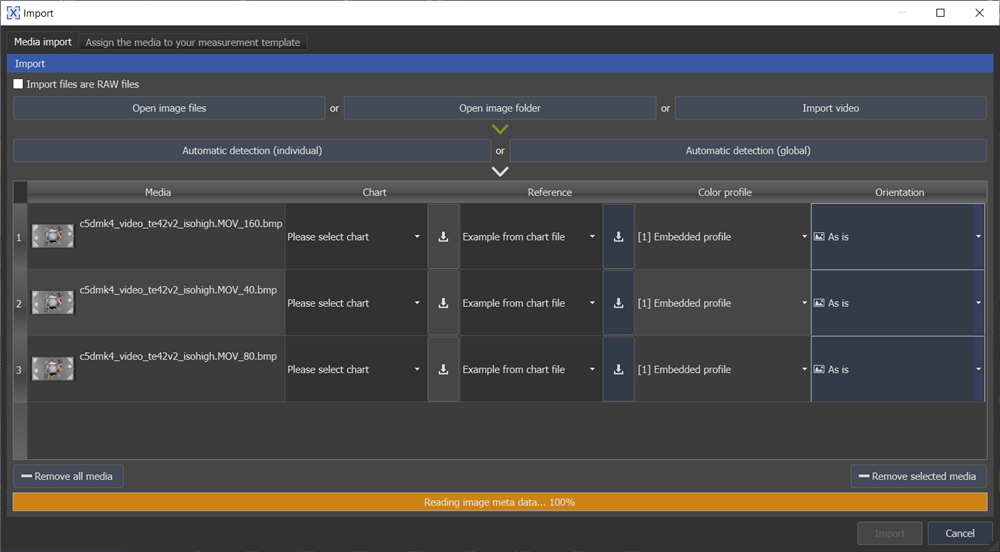

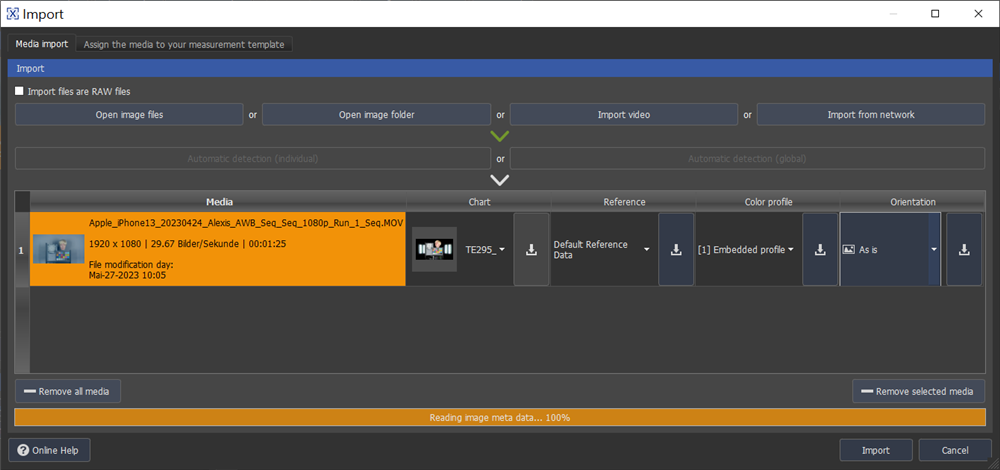

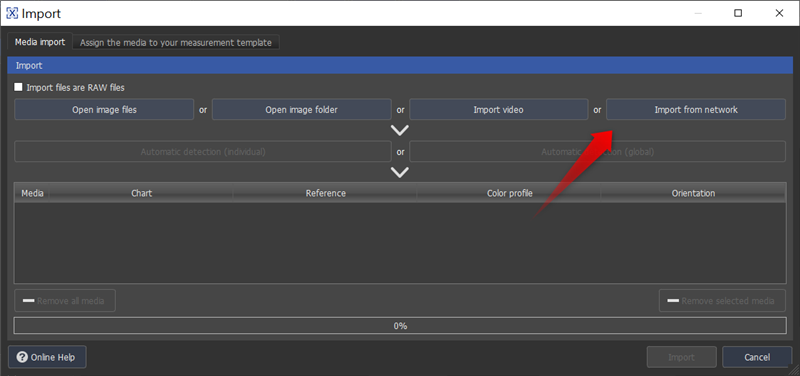

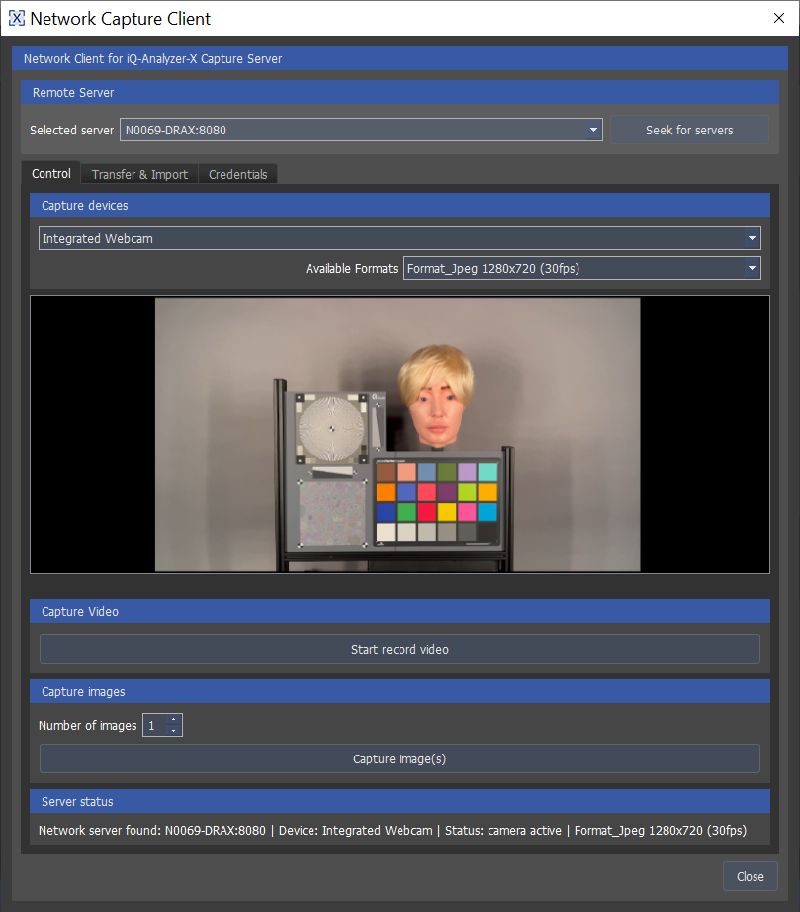

Import Images

If you click on “New Analysis,” the “Import” dialog will pop up. You can either import multiple image files or an entire folder with images. iQ-Analyzer-X currently supports 8-bit and 16bit RGB images in *.tif, *.bmp,*.jpg, *.png format. For 16-bit RGB files, the images must not contain an alpha channel, and they require stating the actual sensor bit depth before import as, for example, a 16-bit image can contain 12-bit data. Some measurements depend on the actual bit depth to provide correct results. If iQ-Analyzer-X detects that the image you want to open is a 16-bit RGB Image, it opens the dialog automatically.

RAW bayer images in .tiff format and binary RAW files are currently supported with a bit depth of 8, 16 or 32 bit unsigned. If your images are RAW bayer, please refer to section RAW images

After opening the test images, they will appear in the “Import” dialog. If you have opened multiple image files, you can allocate the charts manually or automatically. Choose “Automatic detection” (individual) if the test images show different test charts and “global” if all images show the same test chart. To remove a test image, select it and click on “Remove selected images.”

If the chart detection doesn't work, the software will ask you to select the chart manually from the dropdown menu. The dropdown menu also shows “unknown chart” if this is the case. Note that if you want to analyze a custom chart, the automatic recognition won't work because it is not trained for custom charts. If this often happens, you can disable automatic chart classification in the “General” tab in the configuration dialog.

In the “Reference” Column you can select your reference file if you have one. For more information about reference files, please refer to chapter "reference files". You can also assign a color profile and rotate the image in this dialog.

Use the “arrow” button to assign your selection to the following images in the list.

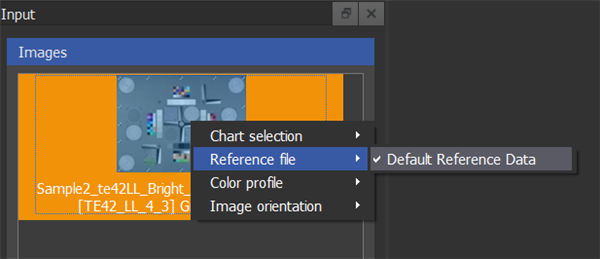

After the import you can still change these parameters for each image by right-clicking on the image in the input dock.

Note, that only specific test charts are supported by iQ-Analyzer-X. Please refer to https://www.image-engineering.de/products/software/iq-analyzer-x for details.

Most test charts will be delivered with a corresponding reference file (*.ref) or a *.pdf that contains your chart's individually measured data. The reference file can be imported in the “Reference files” tab from the “Configure” menu, and this reference file can be allocated in the column “Reference.” If you do not have a reference file, you can also allocate the “Default Reference Data”, which is less accurate and not recommended.

Please note, that if you have certain OECF charts, the software can only detect the layout and not the contrast or type of the chart. For example, if you import an image of the TE269 chart, the software cannot recognize whether it’s a TE269A, TE269B or TE269C. All of them have different patch densities. Therefore, you need to address the chart version by choosing the corresponding reference files in the “Import” dialog. This sequence also applies to chart TE264 and TE270. To do so, you need to import the default reference data of your chart first. The default reference files are located in C:\Program Files\Image Engineering\iQ-Analyzer-X X.X.X\resources\references\templates. How to import reference files is explained in chapter "reference files". If you purchased your OECF chart in 2024 it most likely has an individual *.ref file, which you can download here .

For greater accuracy, we recommend working with measured luminance when capturing transparent OECF charts. The reason for this is that when the chart is placed in the light source, it reflects into the light source, changing the output intensity.

Please refer to chapter "reference files" for information about creating and editing luminance reference files.

If all charts are adequately detected, and the reference files are also correct, click “Import.” The images will appear in the “Input” dock.

Raw Images

If your images are raw files, activate the checkbox “Import files are RAW files” before clicking “Open…”. In this instance, the following dialog for raw file import appears, where you can provide information about the raw file structure. Data formats supported are unsigned integer 8, 16 and 32 bit.

Width and Height: Image width and height in pixels.

Bits per color: Data format of the pixel values.

Header bytes offset: The number of bytes until the actual image data starts. It is important to get the correct starting point of the image data, so that the channel order is interpreted in the right way.

Byte Order: Choose between little and big endian.

Pixel Pattern: Choose the bayer pattern of your raw data, or apply “CUSTOM_4”.

Note, that the shown results depend on the pixel pattern. If you select “Custom_4” the OECF of all channels are shown, but no numerical results are calculated yet. However, you can export the results as .xml and in the .xml you can find the variance and the digital values for each channel and patch to do further calculations as, for example, SNR. If you choose a certain bayer pattern, a Y image is created. Y is a weighted sum of the channels and represents the perceived brightness. All numerical results are then based on this image. For RYCy-CFAs the channels are weighted equally. The Yellow channels are averaged before weighting. RGB-CFAs are weighted R = 0.2125, G= 0.7154 and B 0.0721. The green channels are averaged before weighting.

Bit offset: Images with metadata in a certain bit range can be imported with a bit offset. The bit offset is subtracted from all DVs. For example, if you have metadata in the first 8 bit, you can subtract 256 to get the real pixel value.

Sensor bit depth: The actual bit depth of the data. For example, 12-bit data in a 16-bit container.

If you have many differently structured raw files, you can save your settings for future analysis. To save a setting, you need to provide a name in the top dropdown menu. Once you have a name, the “Save” and “Save new” buttons are available. “Save” will overwrite your setting, while “Save new” will create a new setting in the database. You can access your saved settings via the dropdown menu.

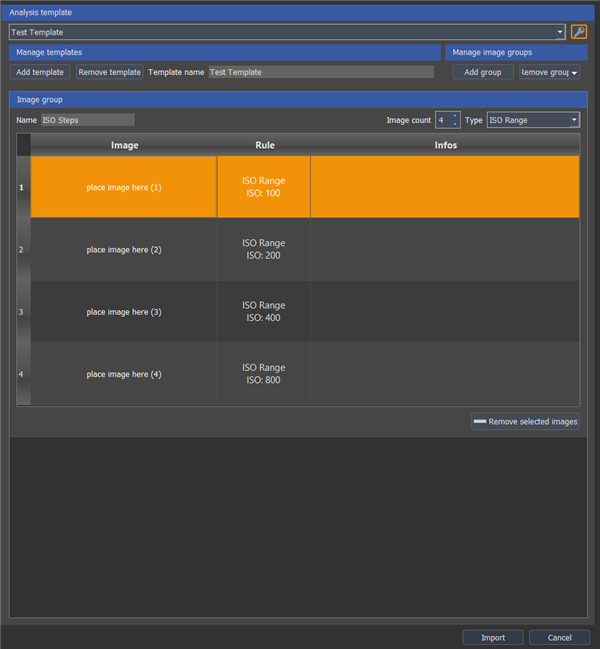

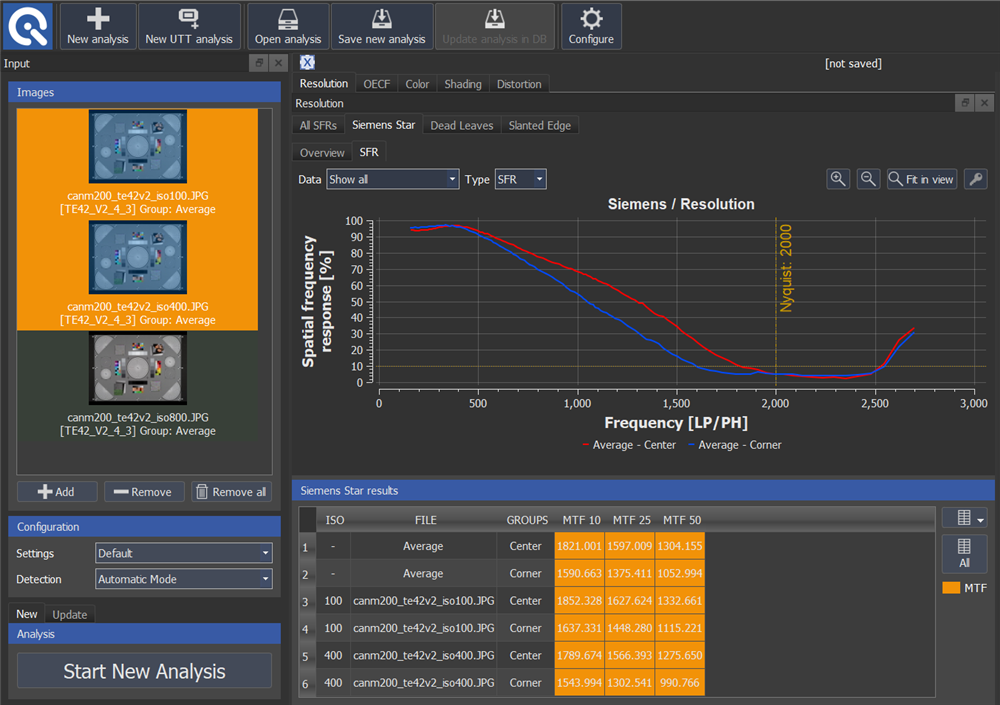

Analysis Template (Image Sequence Analysis)

With analysis templates, image sequences with different apertures or ISO settings can be compared utilizing resolution evaluation. It is also possible to calculate the average of an image sequence or identify the image with the best resolution based on the MTF. You can create templates containing multiple groups, for example, one group for a range of ISO settings and one for a range of aperture settings. Templates are saved to the database and can be selected in the dropdown menu in the “Import” dialog.

Example ISO Sequence with three images:

We create a template for three images captured with different ISO settings in this example.

Click the key symbol to access the template settings.

Add a new template. Change the template name to “ISO Measurement Series,” for example.

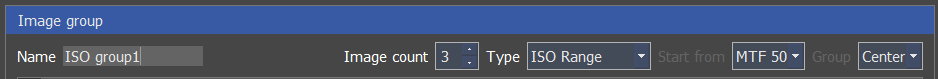

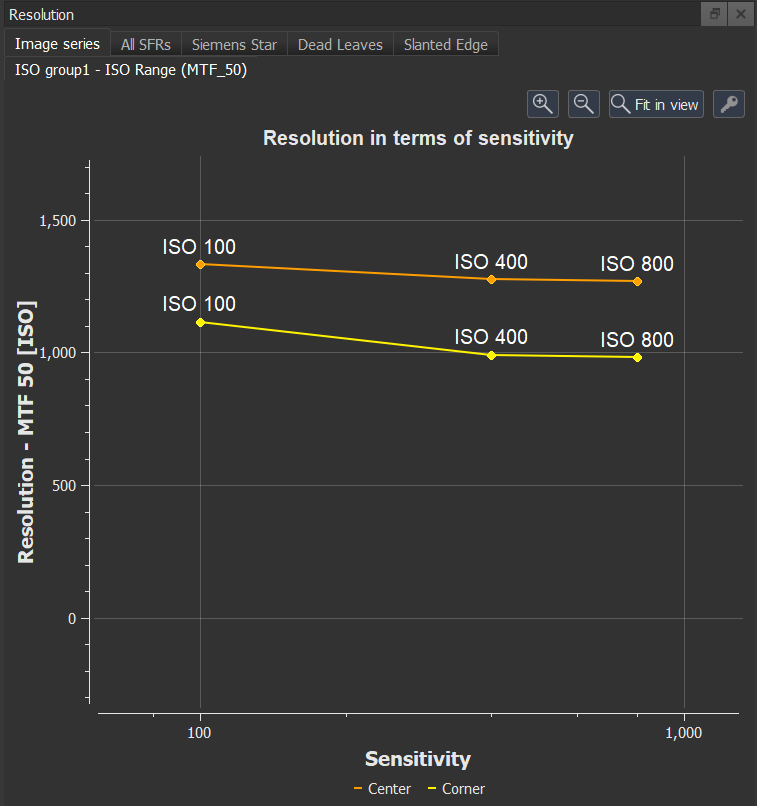

Name the Image Group “ISO group1.” Increase the image count to three. As “Type,” select “ISO Range.” Choose “MTF50” as measurement and “Center” as a group from the dropdown menu. The additional result plot then displays the MTF 50 values of the Siemens stars in the center over the ISO Range.

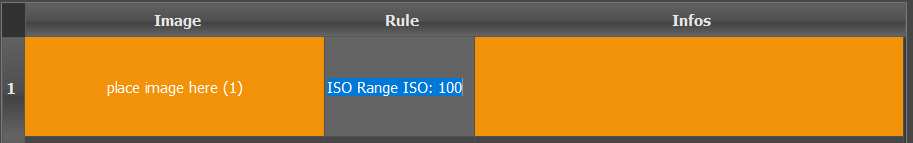

Change the ISO value in the column “Rule” to the corresponding properties of your images. In our case, it is 100, 400, and 800. You can change the value by double-clicking on the field and entering the ISO value.

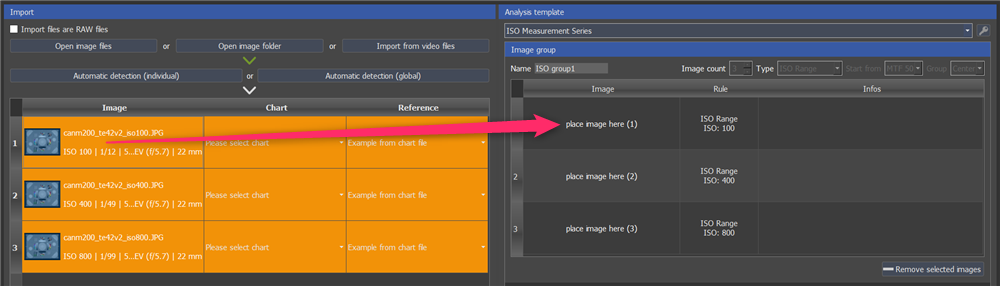

After entering all ISO values, click on the key symbol again to leave the editing mode. Select the three images for analysis and move them to the placeholders.

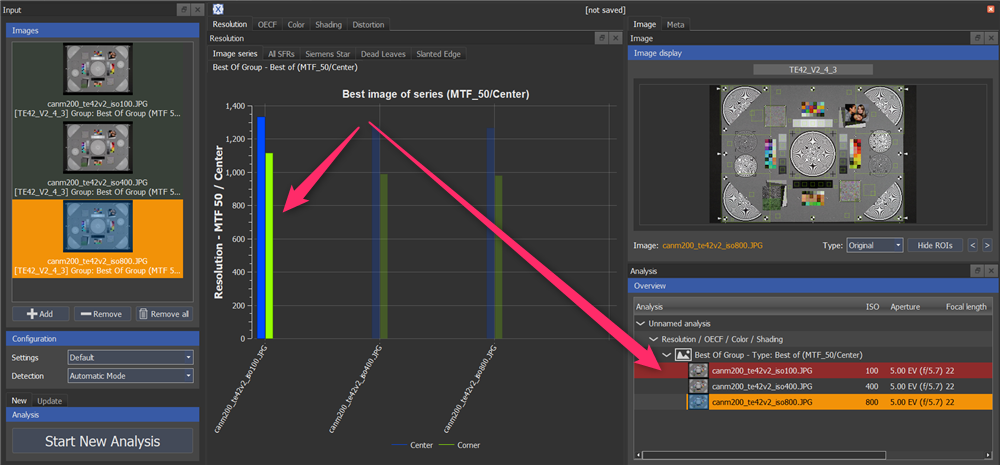

Click “Import” after finishing the allocation of the images and analyze the images. A new tab will be added to “Resolution” called “Image Series,” which shows the MTF over the ISO value.

Average Measurement

Measurement type “Average” can be helpful for measurements that have a significant variance due to the measurement setup. With this option, the average values of the numerical results are calculated, and the plots are adjusted. You can calculate the average of the whole image sequence or only a few images by selecting them in the “Input Dock.” In the following example, only two images are selected from the ” Average “ group, so the plots and numerical results show only the average of the MTF of these two images.

Best Of Measurement

The “Best of” measurement determines the image with the best resolution based on the MTF. An additional “Image Series” tab is displayed, highlighting the image with the best performance. The image is also highlighted in the “Overview” area.

Analyze Images

All imported images are listed in the “Input dock” under “Images.” You can either add, remove or remove all images by selecting the image and pressing the corresponding button.

Under “Settings,” you can define the settings you want to apply to your analysis. You can change and save your analysis settings in the configuration tab under “Configure.”

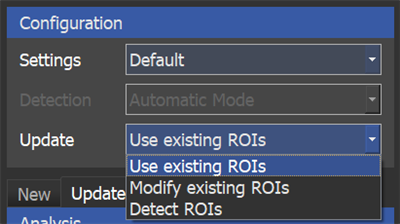

There are two options for running an analysis, “Start New Analysis” and “Update Analysis.”

If you, for example, want to analyze the already imported images with different settings, you can update your analysis by pressing “Update Analysis.” You can also update the analysis with the already existing ROIs, modify the existing ROIs manually or start the automatic detection from scratch by selecting the appropriate item in the drop-down menu.

All results will be updated accordingly. Meanwhile, “Start Analysis” will create a new analysis in a separate tab. If you have two or more analyses opened simultaneously, the currently active analysis tab is highlighted with a brighter text.

ROI Detection

Under “Detection,” you can choose between three modes.

- Automatic Mode

- Semi-automatic Mode

- Manual Mode

In “automatic mode”, the software tries to find all ROIs automatically and analyzes the image immediately. In “semi-automatic mode, the software tries to find all ROIs automatically and opens the “Manual ROI Selection” dialog for further adjustments. In the “manual mode,” the ROIs are placed on the image independently of its content, and the ROI's sizes and positions depend on the principle layout of the assigned chart type.

Note, that automatic ROI detection relies on the image qualities like pixel count, noise, exposure, distortion, alignment of the chart,…

If not all ROIs were detected properly in “automatic mode”, the software asks you if you want to switch to “semi-automatic mode”, which opens the “Manual ROI Selection” dialog in which you can adjust the ROIs. The ROIs that need to be adjusted blink, to make it easier to find them. Note, that they keep blinking even if you changed their position.

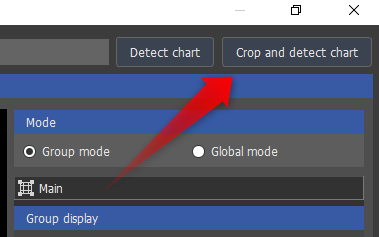

For captured images which do not show the chart full frame, you can use the “Crop and Detect” feature. The crop makes it easier for the software to find the ROIs in the image.

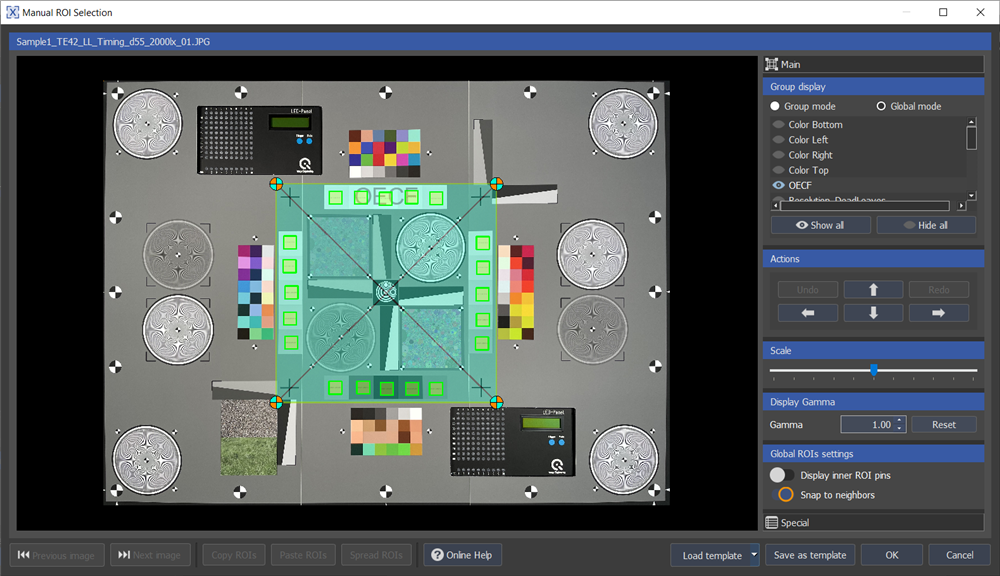

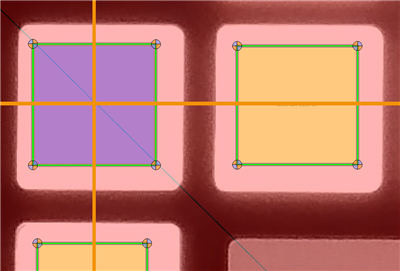

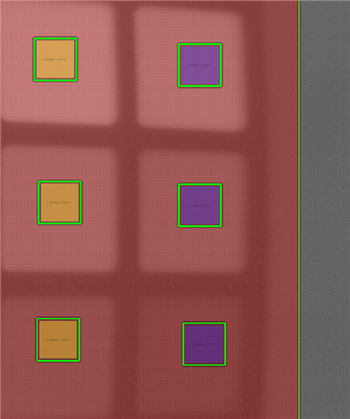

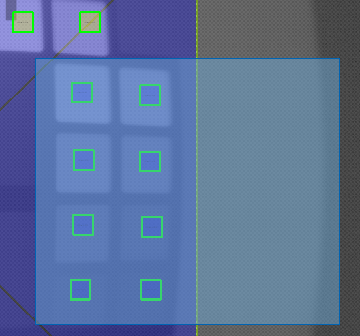

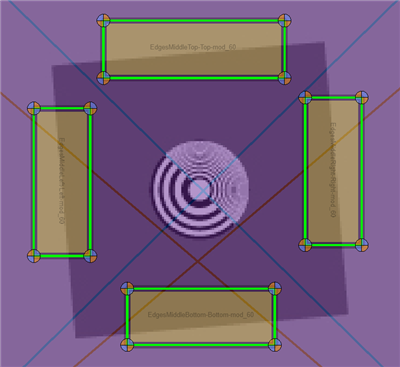

If you have a test image that contains multiple metrics, such as the TE42-LL, you can select the corresponding ROIs for one metric in the “Group Display” section. In “Group Mode” click on the entries in the list to turn them on or off. Once you have selected the desired ROIs, you can change their size and position. To change the size of a single ROI, for example, a color patch, activate “Display inner ROI pins”.

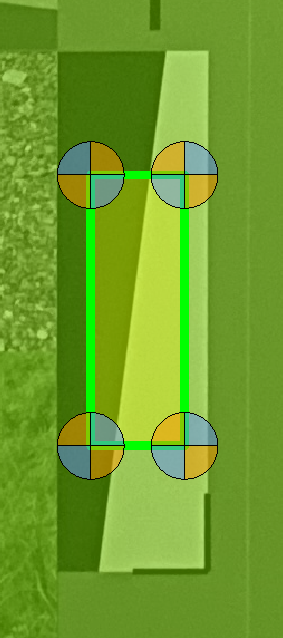

Then grab the ROI on its circle markers. Grab it in the center with a left mouse click and drag it to change its position.

To change the position of all the ROIs of a single metric, you can use the pins at the edges of its surrounding container.

Use the “Global Mode” to change the position of all ROIs of all metrics in the chart at once. This adjustment moves all interior ROIs depending on their relative position to this box. It is useful if all the ROIs have an offset or are affected by distortion or misalignment.

If you only want to change the position of the ROIs, disable the handles by deactivating “Display inner ROI pins.” This option gives you a better view, and it is easier to drag the ROIs. When you enable “Snap to Neighbors”, a cross appears when the ROI is aligned with the center of a neighboring ROI.

Select multiple ROIs with CTRL pressed.

Or draw a rectangle to select multiple ROIs at once.

Especially if you work with HDR images, you might encounter that the images get very dark in the low light regions and the ROIs are not visible anymore. Change the gamma to make these parts brighter and adjust your ROIs.

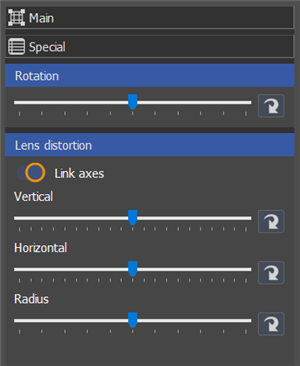

In the “Special” section, rotation or lens distortion can be compensated with the sliders. The sliders are only accessible, if “Global Mode” is activated, as lens distortion typically applies to all ROIs.

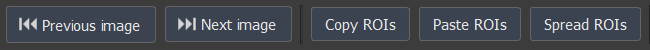

To get a better view, you can enlarge the size of the window or zoom in and out with the scroll wheel. If you have multiple test images with similar content, it's possible to copy the ROIs from one image to another. To do so, select the image which you want to copy the ROIs from with “Previous image” or “Next Image,” click on “Copy ROIs,” then select the image you want to paste the ROIs to and click on “Paste ROIs”.

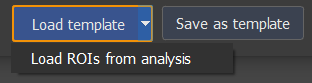

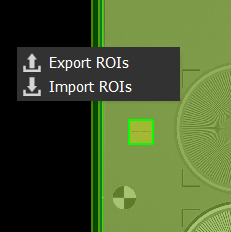

If you're going to apply your adjustments to all images in the stack, click on “Spread ROIs.” With “Save as template” you can save the ROIs for an analysis in a new iQ-Analyzer-X session. Only one template per chart type can be saved. It can be loaded in the next session with “Load template”.

Load ROIs from previous analysis in the database with “Load ROIs from analysis”.

Its also possible to import and export ROIs from an analysis. Right-Click on the background in the “ROI selection” dialog to show both options.

If all targets are correctly detected, press ok to start the analysis. The results show up in the “Analysis Results” Tab.

How to draw the ROI for your target

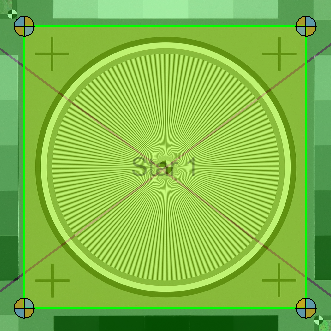

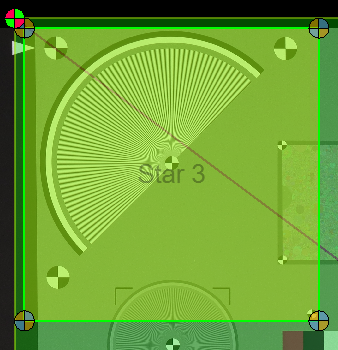

Siemens stars

For all siemens stars, the center b/w marker should be approximately in the middle of the ROI.

If you are working with TE253 or TE268 siemens stars, the inner ROI should cover the entire star plus the surrounding b/w markers or the OECF patches.

The ROI of the center star of the TE42V2 needs to cover the four black crosses surrounding it.

The ROI of the corner stars in the TE42V2 needs to cover the three big b/w marker.

The ROI of the center and corner stars of the TE42LL needs to cover its surrounding four b/w marker.

Note, that the ROI you set is only one of the steps for a proper detection of the siemens stars. Although you might have set the ROI properly, it can still be the case, that the star is not analyzed and shows no results. The “Error log” might help you find the reason for the failure.

Slanted Edges

The bigger the ROI for a slanted edge, the better the results. Depending on the image quality, you might be able to go down to 50px along the edge. The corners of the ROIs must have some distance to the edge.

Dead Leaves

The edges of the Dead Leaves ROI needs to be approximatly in the center of the four corner b/w markers.

Error log

Warning and error messages regarding the analysis of the active session are output in the “Log”. You can open the log by pressing the red warning triangle on the bottom right. Once opened, the triangle will disappear, but you can always check the log under View→Show error log. Note, that the symbol only shows up in case there is important information for the user.

![]()

By default, clicking on “Log” in the bottom of the GUI will also show it.

A red message indicates a significant error, which might make the analysis or a part of it invalid. Yellow messages represent a warning. White messages contain general information.

Common Error Messages and Warnings

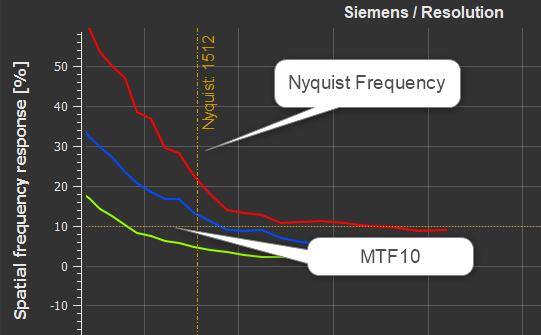

SFR Curve never falls below MTF

The SFR curve does not reach the required modulation before Nyquist frequency to calculate the desired MTF. This can, for example, happen, when a strong sharpening is applied or the resolution of the camera is much better than the resolution of the test chart. It might also appear, when the SFR results are too biased by noise or other artifacts. Is this the case, the MTF value reported is the Nyquist frequency with a negative sign.

ICC profile from image could not be loaded. Used default profile from settings

If iQ-Analyzer-X does not find a color profile in the metadata, it automatically applies the color profile, which is defined in the analysis settings.

WARNING: Example reference file for Color Analysis selected. Please use the appropriate reference file for your chart to achieve more precise results.

In this case, the default reference data has been assigned to the test chart. The default reference data is based on the target values, not the actual measured values. Depending on the type of analysis, it may make sense to work with measured color or density values, as they provide more accurate results.

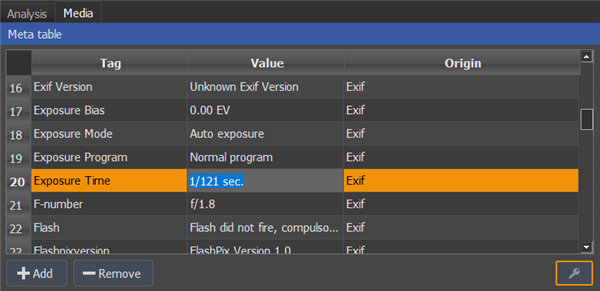

Metadata

iQ-Analyzer-X automatically reads and displays metadata like exif data of the image if available. Under the media tab, the exif data is listed.

By clicking on the key symbol, you are able to modify it. To modify the data, double-click on the cell which contains the value you want to change. The changes will be saved with the entire analysis in the database. This can be useful if your DUT doesn't generate Exif data, but you want to document the settings like aperture, exposure time, etc. Also, for some result plots, the exposure in lux-seconds is calculated based on aperture and exposure time stated in the exif data.

Under the “Analysis” tab you can add customized meta data like operator, test conditions or other. The meta data also shows upon the .pdf report and the .xml result file.

Save Analysis

Click on “Save new analysis” in the toolbar to save the results. Enter the information about the analysis in the dialog.

All fields except “Short name” need to be filled out to make the “Save analysis” button available. Note: If you want to compare two different cameras, you need to analyze each camera, and it is not recommended to mix the results of other cameras in one analysis. Once the camera model and make are saved with the analysis, they are available in the dropdown menu for future evaluations.

Open Analysis

Click on “Open analysis” to load an already existing analysis. In the “Open analysis” dialog, several filters can be applied to help you find your desired evaluation.

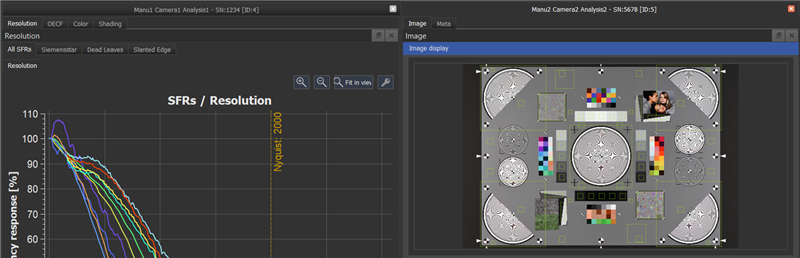

Comparison of Analysis

To compare two analysis, you need to save at least one of them first into your database. With the button “Append to view” in the “Open Analysis” dialog you can then integrate the results of the selected analysis to the currently active one.

Both analysis show up in the “Analysis Overview”. To compare the results, mark the images you want to compare with CTRL key and left-click. The plots and the numerical results now include these images.

In some cases, when there are many targets in the image, the results can become confusing. To get a better overview, use the sorting function in the results table by clicking on the table headline or use the advanced plot settings. To enter the advanced plot settings, click the key symbol at the top of the plot.

Update Analysis in Database

To save changes in an already existing analysis, press on “Update analysis in DB” in the toolbar. You can still change the analysis name, serial number, and the short name in the upcoming dialog.

Delete Analysis from Database

To delete an analysis from the database, all analysis tabs in the current session must be closed, otherwise the Delete button will be grayed out.

Database

With the installation of the iQ-Analyzer-X, a local database is set up where all analysis results can be saved. You can also use a remote database, which is explained in this previous chapter. The database allocates a specific ID to every newly saved analysis. The ID is the main criteria for the database to distinguish between your analysis results. There can be two analyses with the same name but having different IDs.

It might happen, that the database needs to be updated when you update iQ-Analyzer-X. If it is required, you will be asked at program start, if you want to update the database.

We recommend that you back up your database before updating the software, just in case something goes wrong.

In the “Configuration” dialog under the “Maintenance” tab, you can see the currently used database and its version.

Here you can create or restore backups of your database and change the folder, where your database is located. To change the folder, click on the “Gear” symbol.

The database is a *.db file and by default the images are not stored in a backup. Check “Create backups including images” to include images. The symbol in the column “Type” shows, if images were included or not.

Database Migration Tool

If you started with a local database and want to copy your data to a remote ODBC or vice versa, you need the Database Migration Tool.

Start the Database Migration Tool from the “Help” menu.

To start the tool, close iQ-Analyzer-X.

In the dialog box that appears, select the source database on the left and the target database on the right. Enter your credentials if necessary. Finally, click “Start database migration” to start the process.

The progress is shown in the progress bar. When the migration is finished, a confirmation appears.

After confirmation, it still might take a few seconds to update the database information in the dialog with the new properties. At last the “Current source database content” and the “Current destination database content” should be equal.

Results

The results are provided numerical and in graphical representations. The plots that appear depend on the chart you are using. If you analyzed multiple images, the plots and the numerical results show the results of the marked image. To display the results of more images at once, select them using the Ctrl key.

If a legend is shown with a plot, you can click on the legend to view or hide the legend's entries in the plot. Only Q1 and Q2 are shown in the graph in the example below, and all the other legend entries are hidden.

Zoom in or out of the plot using the mouse wheel. Change the plot's position by simply clicking and dragging.

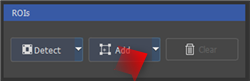

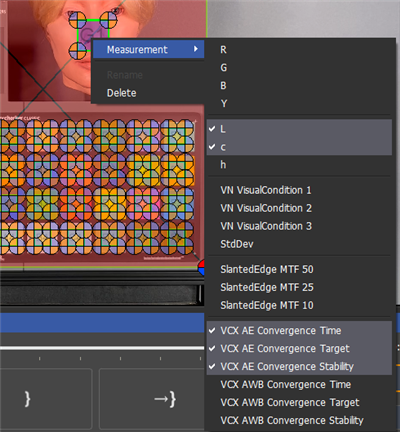

The corresponding numerical results are shown in the table below the graphs. You can define the measurements you would like to include in the table by checking them in the dropdown menu on the right side.

Note, that not all parameters, shown in the list, are calculated. By default, the parameters, which are not calculated, are not checked in the list. These parameters do also not have any color coding. They have a gray background and show zero. Click on “Reset” to switch to the default measurements.

The results that belong together are marked in the same color. You can easily copy and paste the table to a spreadsheet software for further processing. Just select the cells you want to copy, or click on the top left square to select the entire table.

Or use the context menu which you can open by right-clicking a random cell.

Tip: You can sort the results in the table alphabetically or numerically by clicking on its headline. This way you can, for example, find the best MTF10 or compare two images in the rows next to each other.

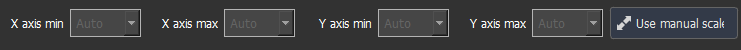

Advanced Plot Settings

Some of the result plots offer advanced settings. You can access these options with the “Key” button on the top of the plot.

In the advanced settings you can adjust the scale of the X and Y-axis. Click on “Use manual scale” to activate the dropdown menus.

On the bottom of the plot some more options appear.

Channel: Depending on the chart and its metrics, you are able to choose between the R, G, B and Y channel.

Group by: Depending on the chart and the metric you are able to view the result of different groups. For example, Siemensstars on TE42 LL, if you choose the SFR Plot of the Siemens Stars, you can group the results by Segments, Stars, Groups or Image. Segments are parts of the Siemens Star, which is the smallest SFR measurement on a star. One segment is an eighth of a Siemens Star in a certain direction. “Stars” shows the SFR of the complete Siemens Star. “Groups” shows the center stars and the corner stars SFR separately. “Image” shows the average SFR of all Siemens Stars.

Tip: If you want to compare several images, mark them in the “Input Dock” and choose “Image” under “Group by”. Now you can see the average of all targets in each image in the plots and the results table.

Graphs: You can choose, if you want to see the “Mean of Selection” or each “Single Image”.

Unit: Choose the unit for the axis of the plot. For resolution you can choose between linepairs per picture height (LP/PH), linepairs per pixel (LP/PX) and linepairs per millimeter (LP/mm). For LP/mm you need to provide either the physical height of the sensor and its height in pixels or the pixel pitch. A dialog shows up when LP/mm is selected.

![]()

Legend: Define the position of the legend.

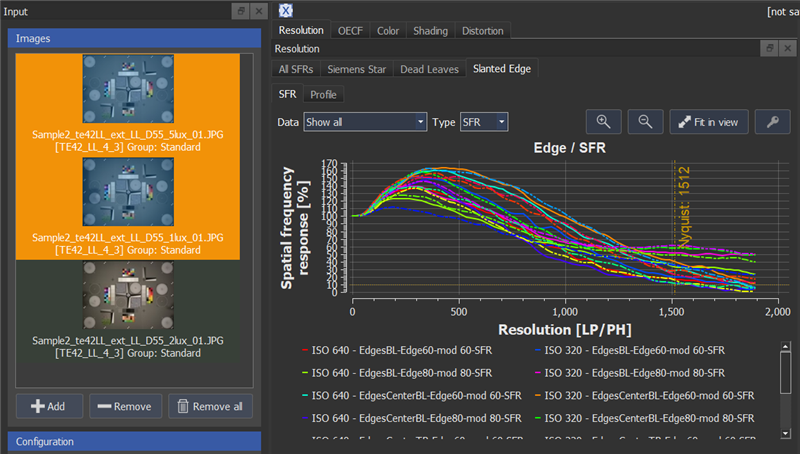

Resolution

Image resolution is the ability of a digital camera to reproduce the details of a scene. Resolution is an essential image quality attribute related to the overall image quality perceived by a human observer. Various factors influence image resolution, including the lens quality, alignment of the components, ideal focusing, exposure time, a sensor with optical components in front of it (low pass filter, IR filter, etc.), and aperture. All of these components are responsible for reproducing the details of objects within a scene.

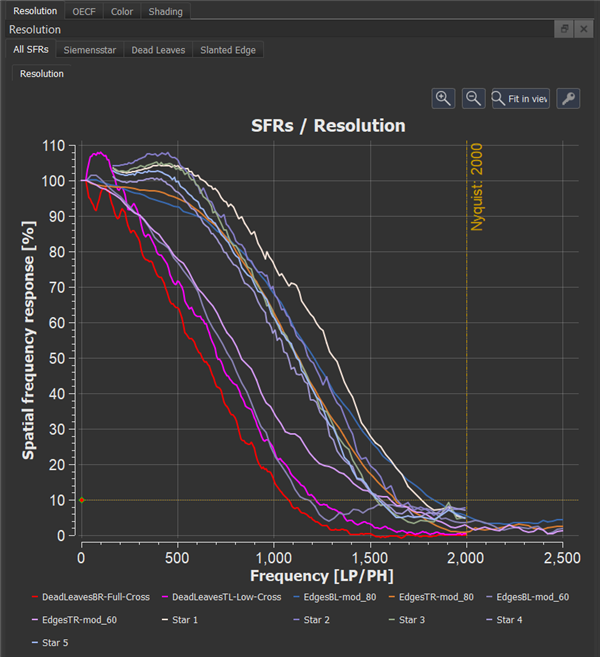

iQ-Analyzer-X provides methods, each with different characteristics, to measure resolution. These include Siemens Star, Slanted Edge, Dead Leaves. The result in each case is a Spatial Frequency Response (SFR) or Modulation Transfer Function (MTF). Both designations are used equally in plots and numerical results.

For more information about the methods, please visit our homepage.

Another target for resolution measurement, currently only available for the TE42-LL UW, is the Tartan Target. This measurement is based on work within the VCX group and is still in beta status. A rough description of the method is in this paper:

VCX Version 2023 The latest transparent and objective mobile phone test scheme

Graphical Results

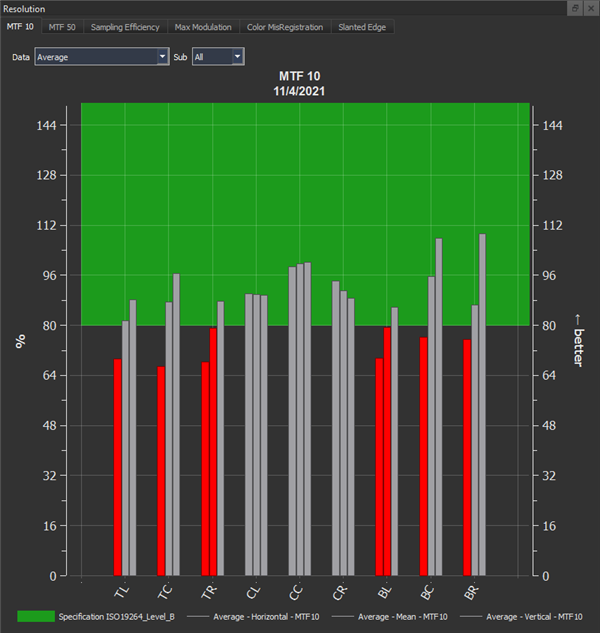

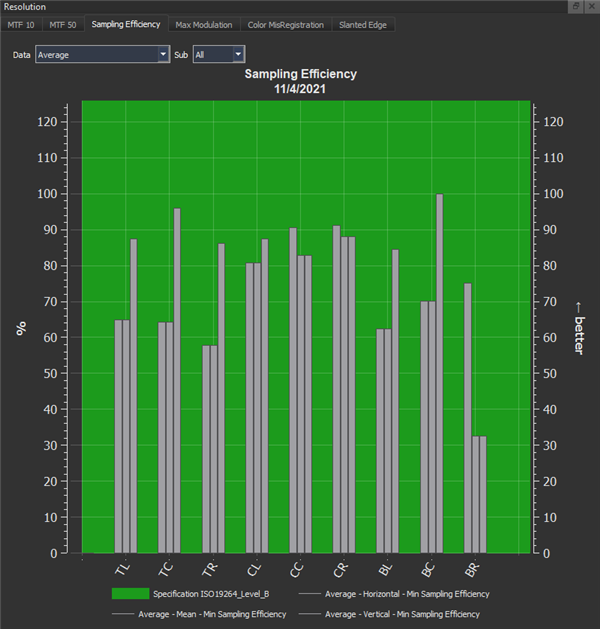

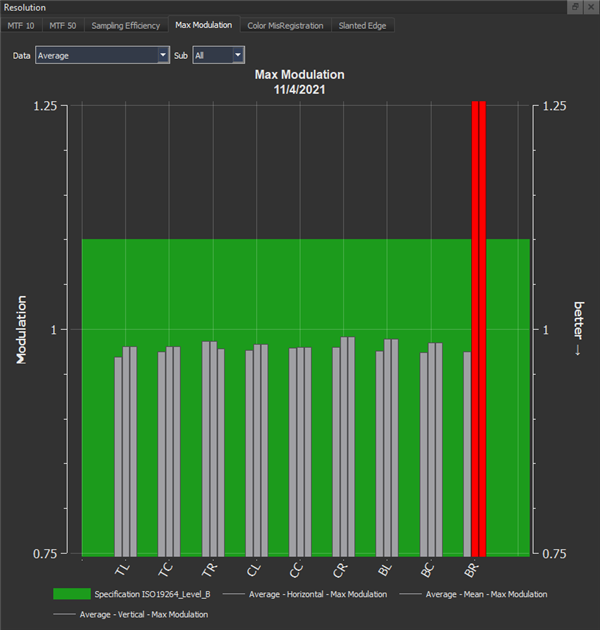

The MTF10 and Nyquist frequency are represented with the orange dotted lines shown in the graphs.

All SFRs

SFRs of all selected resolution measurements such as slanted edge, siemens star, or dead leaves are shown in one graph in this tab. If there are multiple targets for one measurement in the chart, the average will be displayed. The targets used for the results will be highlighted orange in the “Image” tab. Depending on the measurement, the curve might begin and end differently. A slanted edge SFR starts at frequency zero and ends above Nyquist frequency due to applied oversampling. The highest and lowest frequency of a siemens star is defined by the spatial frequency at the center marker and its circumference, and the dead leaves goes from zero to Nyquist frequency only.

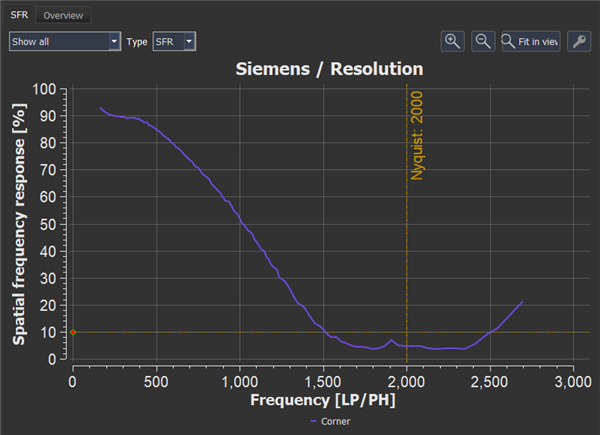

Siemens Star

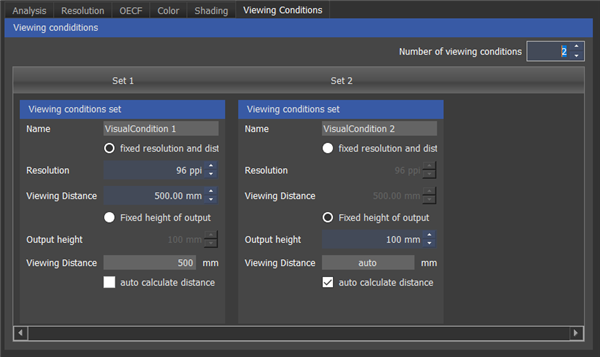

The SFR of a single Siemens star or all Siemens stars can be displayed in this plot. With “Type,” you can choose if the SFR is weighted with the viewing conditions to retrieve a vSFR and vMTF. The viewing conditions can be edited in the "Viewing conditions" tab. If you choose a vSFR, the graph's Contrast Sensitivity Function is added as a painted gray line.

Note that the plotted line of the MTF starts at the lowest frequency the siemens star can represent. The modulation at this frequency may not be 100%, depending on the quality of the camera system.

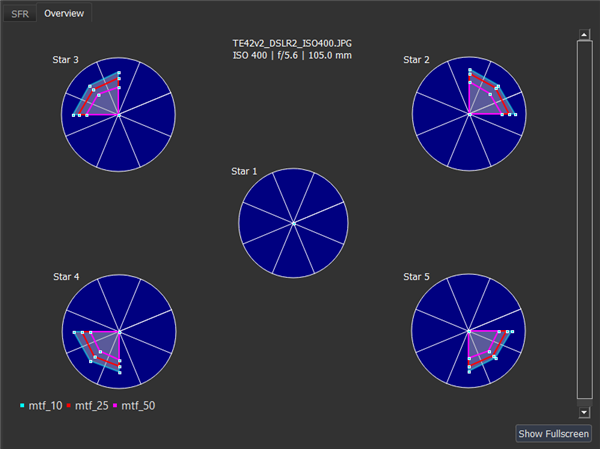

The overview shows a circle for every Siemens star in the chart, divided into eight segments. The image below shows the segment IDs. Please refer to the advanced plot settings if you want to see the MTFs of the single segments. The MTF10, MTF25, or MTF50 are calculated for each segment, giving you an excellent look at the resolution differences depending on the direction. The single circles show the percentage of how close the MTF10, MTF25, and MTF50 are to the Nyquist frequency. The circle's outline represents 100 percent of the Nyquist frequency, whereas the center represents zero percent. So the closer the MTFx curve is to the outline, the better.

The image below shows the IDs of the different segments.

Dead Leaves

For the SFR plot, please refer to "Siemensstar".

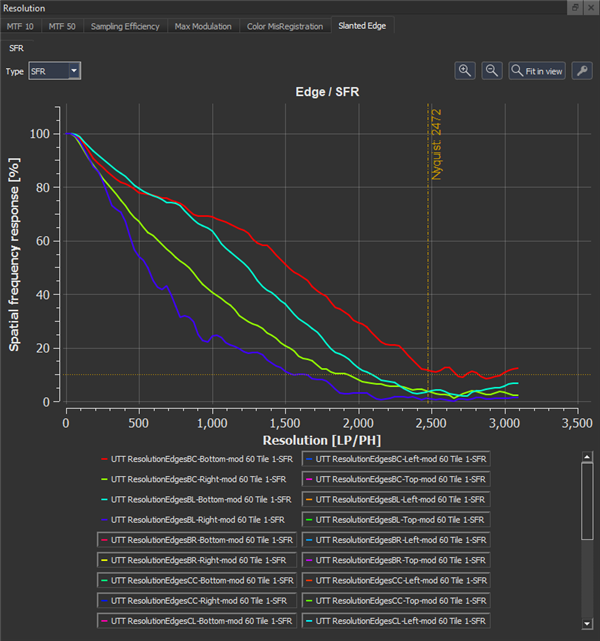

Slanted Edge

For the SFR plot, please refer to "Siemensstar".

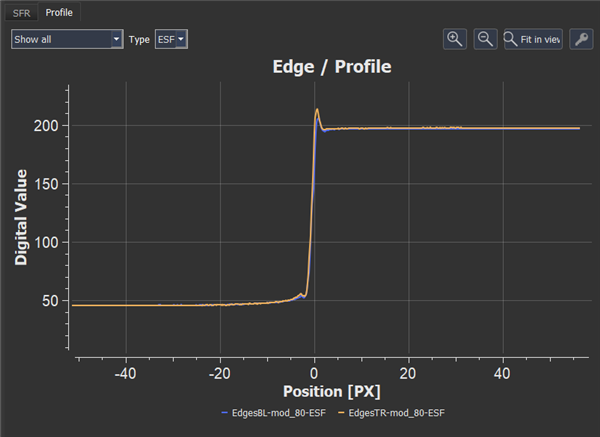

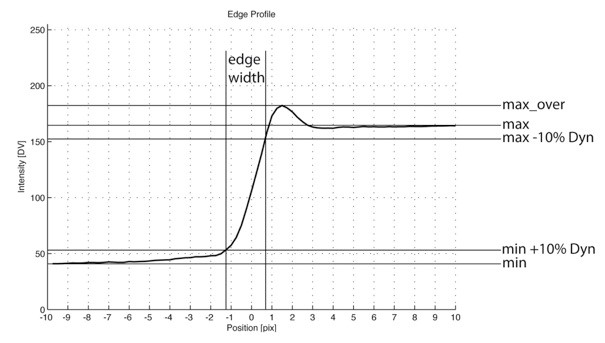

The “Profile” plot shows the edge spread function of the slanted edges in digital value over the position. The edge spread function plot is a valuable tool to identify sharpening in the image.

Tartan Target(Beta)

The Tartan Target is a pattern which consists of a certain number of spacial frequencies in tangential and sagittal direction. The Tartan Target analysis shows the SFR of the given spatial frequencies. Depending on the image quality, not all frequencies might be detected. The SFR between the frequencies is linearly interpolated.

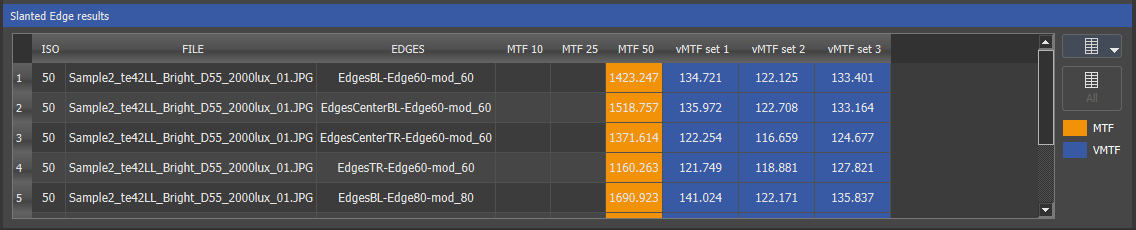

Numerical Results

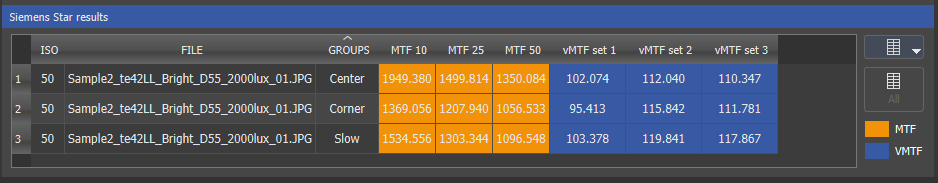

ISO: Shows the ISO setting of the camera, if available.

FILE: Shows the Filename.

GROUPS: If you captured a test chart with multiple targets, for example, the TE42 LL, targets might be grouped, and the results will show the group's average if you select “Show All” under “Data” in the graph.

EDGES: The identifier of the slanted edge.

MTF 10, MTF 25, MTF 50: The MTF values refer to the spatial frequencies that reach a particular modulation. For example, the MTF10 shows the spatial frequency that still reaches a modulation of 10%, whereas the MTF25 shows the spatial frequency that reaches 25% modulation. If the MTF curve doesn't reach such modulation until the end of the MTF curve, the MTF result shows the Nyquist frequency with a negative sign. Note, that the starting frequency and the length of the MTF/SFR curves depend on the measurement method. Slanted Edge and Dead Leaves always start at a frequency of zero, while the Siemensstar MTF starts at the lowest available frequency of the star. The Dead Leaves SFR is only calculated till Nyquist frequency. The frequency is expressed in LP/PH (line pairs/picture height) by default, but can be changed to line pairs per pixel or mm.

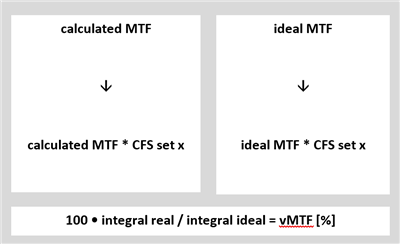

vMTF SET1-SET3: This measurement is similar to visual noise and quantifies how well a human observer can recognize noise. The vMTF (visual MTF) is also referred to as acutance! It implicates the three defined viewing condition sets. The calculated and the ideal MTF are multiplied with the contrast sensitivity function (CSF) and depend on the viewing condition sets for visual noise. The two integrals are divided. When multiplied by 100, you get the vMTF expressed in percentage.

Edge modulation: The modulation of the slanted edge in the linearized image. The value should be close but not necessarily equal to the modulation of the target.

Edge width (0-100%) and Edge width (10-90%) in px: The edge width is specified for 0-100% and 10-90% of the maximum modulation of the edge. It is the distance in pixel between two points in the edge profile with a certain modulation. The example below shows the edge width for 10 to 90%. The y-axis is the intensity in digital values for an 8-bit image from 0 to 255. The x-axis represents the position related to the edge. So, value 0 is the position of the maximum of the first derivative of the edge profile. For example, a value of 4 indicates that 4 pixels are right of the edge. Therefore, a value of -4 means 4 pixels are left of the edge. The left always represents the low intensity, and the right the high-intensity side of the edge.

Maximum digital value: Indicates the average DV of the bright part of the edge.

Minimum digital value: Indicates the average DV of the dark part of the edge.

Overshoot and Undershoot: These metrics are calculated based on the edge profile and specify the undershoot and overshoot resulting from sharpening in the image. It is defined as (max_over-max)/max*100 for overshoot and the opposite way for undershooting.

Fit error (px): An ideal line along the edges has to be determined for the SFR-Edge approach. The fit error shows how well this line has been fitted into the real image data—the lower the value, the better the fit.

Tartan SFR(Beta): Is the area under the measured SFR. A value of one would mean that the SFR is at 100% up to the Nyquist frequency.

OECF

The Opto Electronic Conversion Function (OECF) can be determined with a grayscale target in a test chart. The OECF describes how a digital camera transfers the luminance of a scene into digital values in the image.

The test chart needs to be illuminated homogeneously to determine the OECF. In ISO 15739:2013, the digital value of the test chart background should be equal to 118. The OECF gray patches are also applied for Noise related and Dynamic Range measurements.

Most of the OECF plots have luminance, luminance(log) or exposure on the x-axis. Exposure requires the aperture and exposure time from the exif data to be calculated. If your plot shows only a vertical line, you may need to add these values to the Exif data in the Media tab under Meta. To do this, click on the key icon and then double-click on the corresponding entry.

Graphical Results

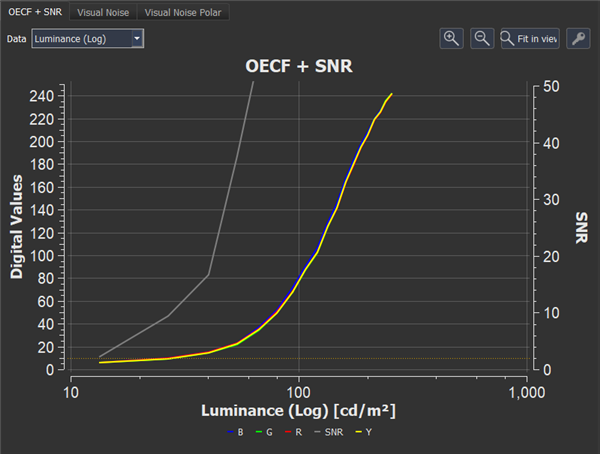

OECF + SNR plot

The OECF + SNR plot shows the optical-electronic transfer function and the SNR for the R, G, B channels, and Y. In the “Data” drop-down menu, you can define the parameter and scale for the x-axis. The SNR curve is the gray curve and its scale is on the right. The dotted red lines represent the lower and upper limit for DR calculation.

Note that even if the camera doesn't saturate, an upper limit is defined, which is the highest DV, and dynamic range (DR) is calculated. This DR value is then the minimum DR of the camera, but not the maximum DR. This basically means that if “Saturation reached” = 0, the minimum DR is shown in the results, if “Saturation reached” = 1, the maximum DR is shown in the results.

If the camera doesn't saturate, check if the chart contrast is suitable for the device under test and if the exposure was set correctly.

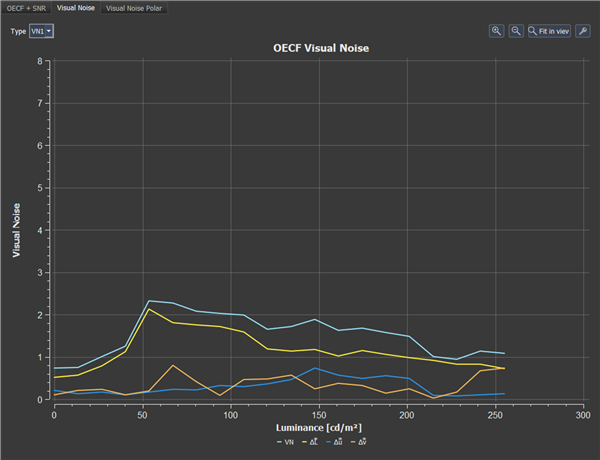

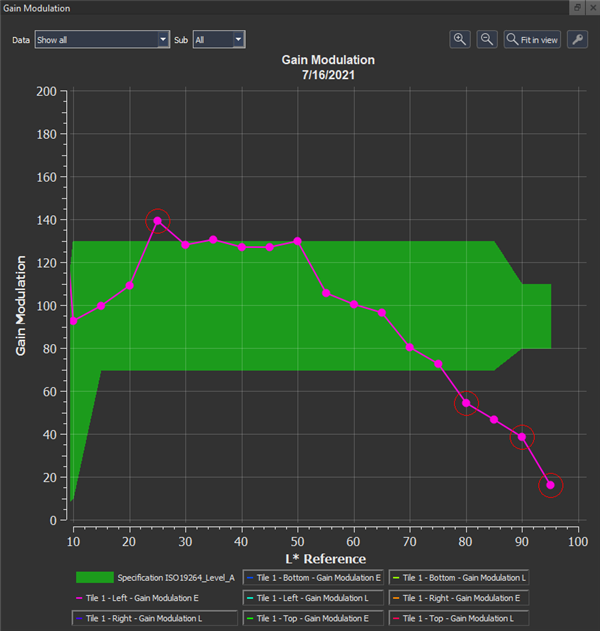

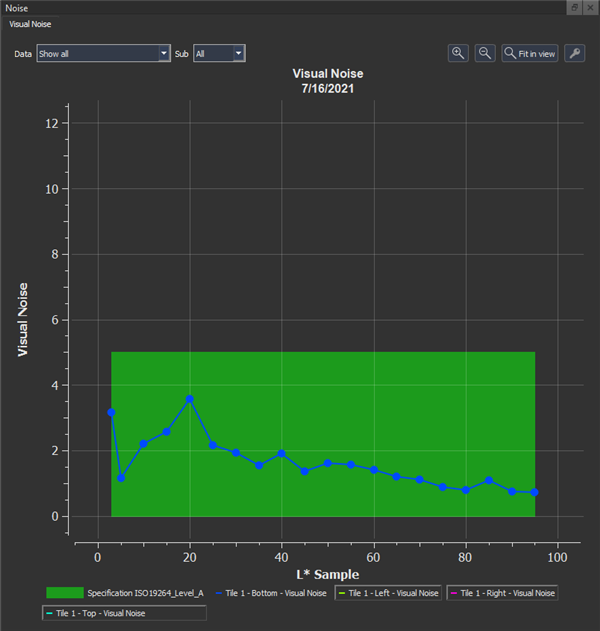

Visual Noise

The visual noise graph shows the visual noise determined over the luminance values according to ISO 15739. The curves named Delta L*, Delta u*, and Delta v* show the share of the individual parameters to the overall visual noise. The visual noise depends on the viewing condition set in the configuration menu. You can exhibit visual noise for the three viewing conditions (VN1, VN2, VN3), with the “Type” drop-down menu in the upper left corner.

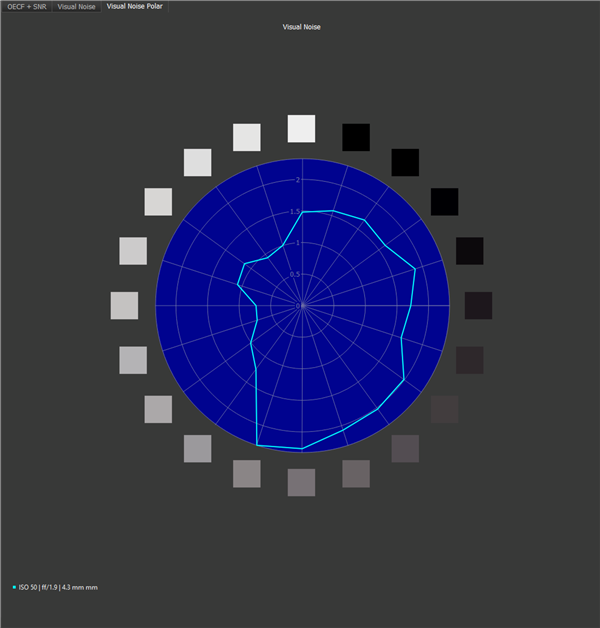

Visual Noise Polar

Visual Noise Polar: The polar plot shows the visual noise over the gray patches in circular arrangement. The patches are sorted by number, from first to last patch. The brightness of the patches is determined by their gray value in the test image.

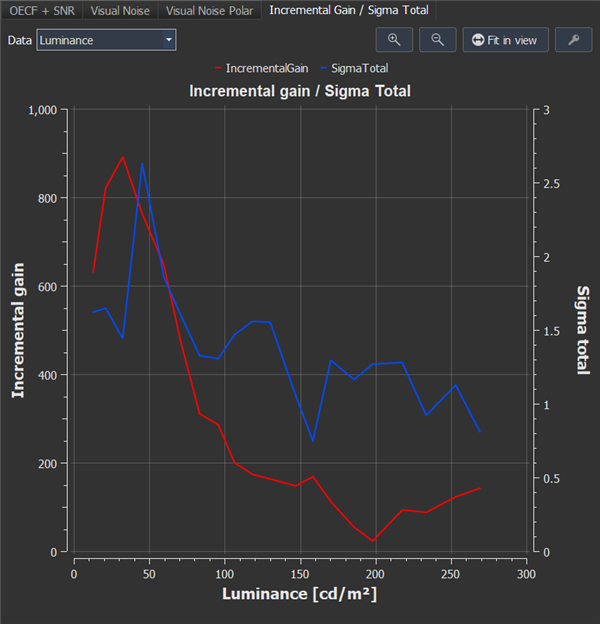

Incremental Gain/Sigma Total

Displays the incremental gain and sigma total values for each OECF patch.

Numerical Results

OECF+SNR

SNR is defined as the ratio of the signal value to the standard deviation of the signal value. iQ-Analyzer-X calculates a Y (luminance) image and uses this for further calculations. The results are also indicated as digital values [DV]. The following calculations are based on ISO 15739:2013 which is currently applied in iQ-Analyzer-X. For the chart-based OECF, the reference luminance (Lref) shall be determined as the luminance corresponding to a digital level of 245 (for sRGB 8 bit) on the OECF function. For a more detailed description, please refer to the ISO paper.

LREF: Luminance corresponding to the digital value of 245

RREF : Log luminance value at the reference luminance.

S-1: The inverse of the camera OECF curve, S

I: digital value = 245

SNR total: Total noise means all unwanted variations captured by a single exposure.

Total standard deviation: Standard deviation of the total noise for a single image and multiple images when analyzing “n” images.

The signal-to-noise ratio is determined by:

SNR Total (dB): SNR TOTAL is specified in dB.

Mean Visual Noise: The numerical value for Visual Noise is a weighted sum of the standard deviation of each channel in the CIE-Luv color space. To give further insight into the noise characteristics, we also provide the visual noise metric for all three viewing conditions, which can be specified in the settings. In the results table the visual noise measurements are color coded.

Max Visual Noise: The maximum visual noise.

Mean ΔL*: Mean standard deviation in CIE L*.

Max ΔL*: Maximum standard deviation in CIE L*.

Mean Δu*: Mean standard deviation in CIE u*.

Max Δu*: Maximum standard deviation in CIE u*.

Mean Δv*: Mean standard deviation in CIE v*.

Max Δv*: Maximum standard deviation in CIE v*.

Dynamic range: The dynamic range is provided in f-stops, densities, and dB. It applies to ISO 15739:2013. The ISO DSC (Digital Still Camera) dynamic range is the ratio of the maximum unclipped luminance level Lsat to the minimum luminance level that can be reproduced with a signal-to-noise ratio of at least 1, Lmin.

Note that even if the camera doesn't saturate, an upper limit (Lsat) is defined, which is the highest DV, and dynamic range (DR) is calculated. This DR value is then the minimum DR of the camera, but not the maximum DR. This basically means that if “Saturation reached” = 0, the minimum DR is shown in the results, if “Saturation reached” = 1, the maximum DR is shown in the results.

If the camera doesn't saturate, check if the chart contrast is suitable for the device under test and if the exposure was set correctly.

The default threshold is SNR=1.

If the threshold cannot be reached, a 2.0 density “black reference” calculates the dynamic range to avoid black level clipping problems.

The value for Lmin shall be calculated as

σtotal (2.0): The black total noise measured at a density of 2.0.

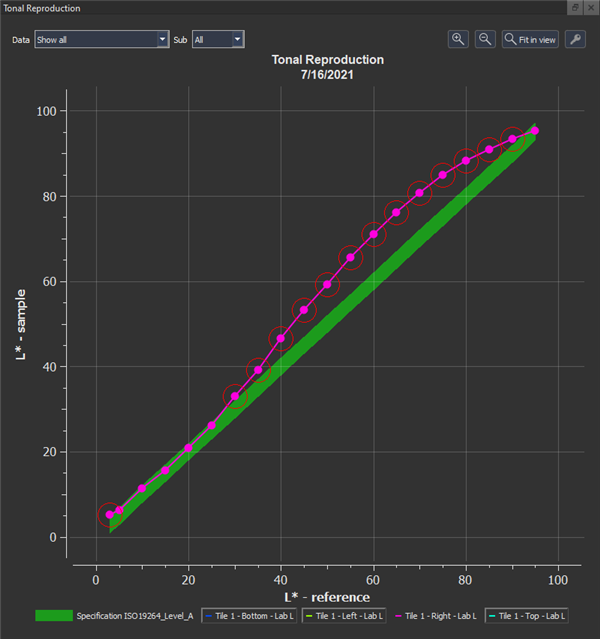

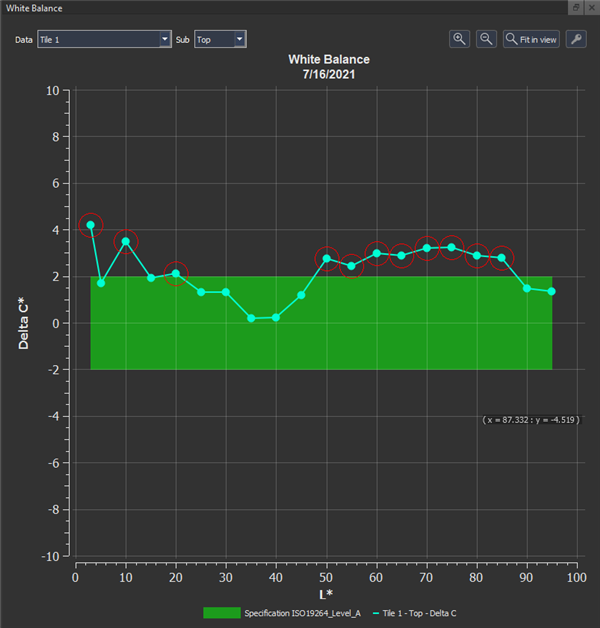

Color

Camera color characterization is an essential step in the color image processing pipeline. It evaluates how the camera module translates RGB raw data from the sensor to the desired color space. Improper color calibration and characterization can lead to false-color reproduction, thereby hurting an image's overall image quality. The color reproduction is usually described with the Delta E metric, which represents the color difference of the color in the test image to its reference color. Note that there are different formulas for the calculation of Delta E. Therefore, you also need to state the applied formula.

Graphical Results

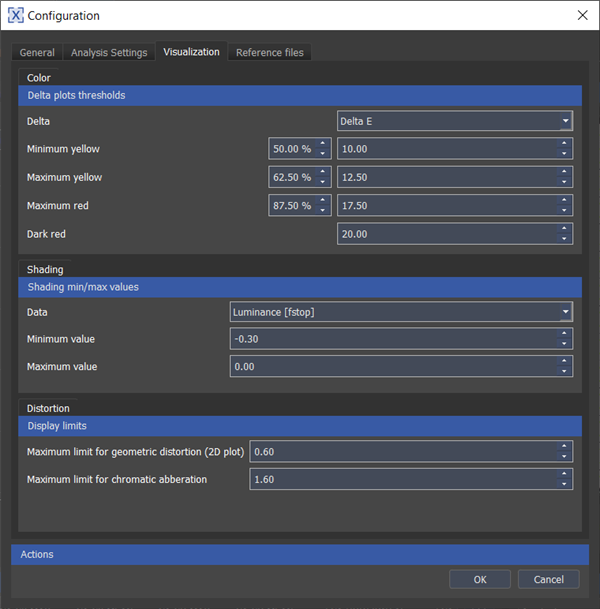

Delta Tables

The “Delta tables” tab shows a color-coded square for each color patch in the test image. These squares also exhibit the numerical parameter value selected in the drop-down menu. You can choose between Delta E, Delta E_ab, Delta L, Delta C, Delta H, and Visual Noise. The scaling of the color coding can be adjusted under “Visualization” in the “Configure” dialog.

“Visual Comparison” compares the color in the test image and the color of your reference.

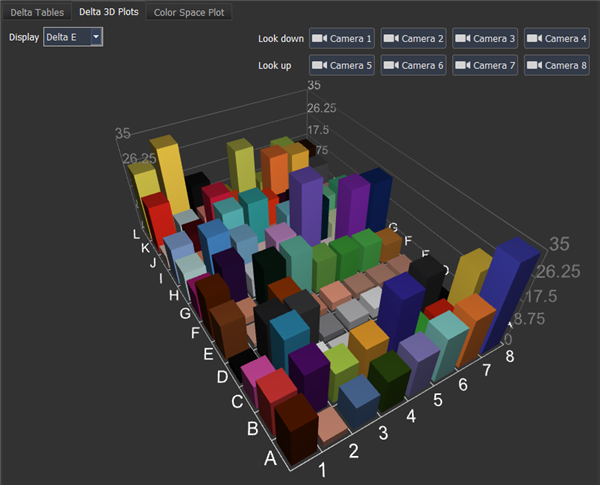

Delta 3D Plots

This plot shows the Delta values in 3D bars. You can change the perspective by using the different camera positions or dragging the plot with your mouse. In case of negative values, it makes sense to use the bottom camera views.

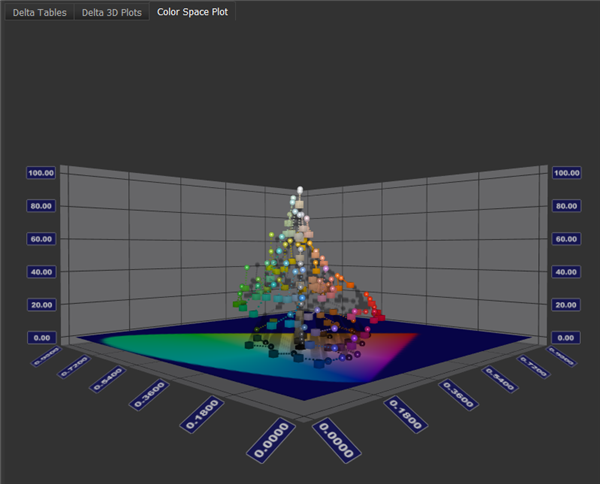

Color Space Plot

The calculated colors of the image and the reference are displayed in the CIE xyY color space, where x and y are the chromaticity coordinates, and Y is the luminance. The colors of the image under test are represented by a sphere and the reference colors by a cube. Click on the geometries to see its CIE x, y, and Y values.

Numerical Results

The mean and maximum values are stated for different groups, defined in the reference file. A group can, for example, contain only the skin, color, or neutral tones. “General” groups all patches.

Delta E: The iQ-Analyzer-X calculates Delta E from two Lab data sets, the reference, and the image sample set. You can choose between four Color Difference Formulas for calculating Delta E under “Analysis Settings,” with the most common calculation being CIE1976.

CIE1976:

If you express the Lab in polar coordinates, you get LCH, where L is the luminance, C the chrominance, and H the hue. Delta E indicates the overall difference between reference and sample. It might also be interesting to look at the difference between Luminance Delta L and Hue Delta H to get more detailed information about the deviation.

CIE1994 is calculated based on the CIE LCH color space and includes weights for Luminance, Chroma and Hue to address perceptual differences.

CIE1994:

In iQ-Analyzer-X, the following parameters for graphics and photography are used.

kL = kC = kH = 1

SL = 1

SC = 1 + 0.045 Csample

SH = 1 + 0.015 Csample

CIE2000:

Compared to CIE1994, the rotation term is added as the fourth element and only takes effect in the blue region.

CIE2000 SL1:

The same formula as CIE2000 with the factor SL set to 1.

Delta E_ab: Delta E_ab is similar to Delta E but doesn't take the Delta in luminance, into account.

Delta L*: Delta Luminance is based on CIE LCH color space and represents the difference in luminance.

Delta H*: Delta Hue is based on CIE LCH color space and represents the difference in color.

Delta C*: Delta Chrominance is based on CIE LCH color space and represents the difference in color saturation.

VN SET1-3: Visual Noise is described in ISO 15739. It correlates much better with the human perception of noise than a standard SNR measurement, and is stated for three viewing conditions.

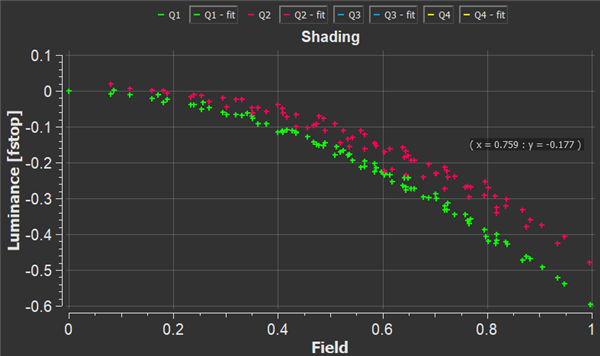

Shading

The shading results show how uniform a camera reproduces a test image of a flat field, meaning a surface with uniform intensity. This test can be an image of a uniform test chart like the TE255 or an image of a light source with a uniform opening like the CAL series.

Please note, that currently, no linearization is available for the shading analysis.

Graphical Results

The plots offer different metrics for Shading, Color Shading and Noise which can be selected in the dropdown menu.

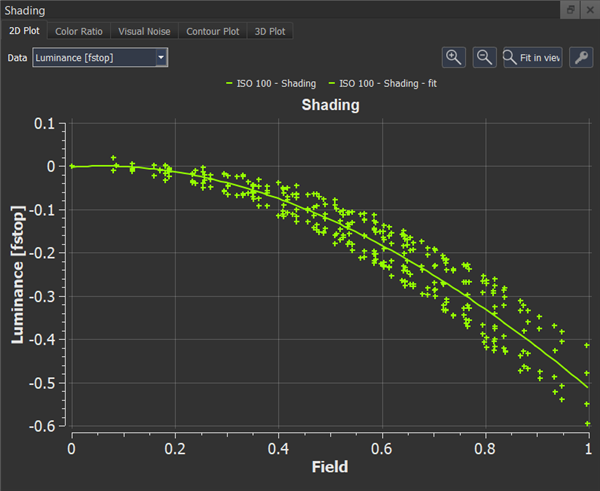

2D plot

The “2D plot” shows the shading measurements over the field of the test image. The field is a line drawn from the center of the test image to the corner, with the image center being field=0 and the corner being field=1. All shading ROIs are mapped to the field along their radius.

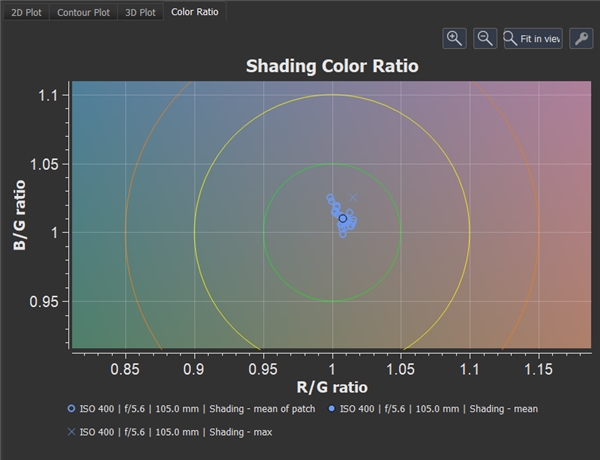

Color Ratio

The “Color Ratio” plot shows the ratio of blue and red over the green channel and is, therefore, suitable to show color shading in the image.

- “Shading - mean of patch” is based on the average ratio in a single patch.

- “Shading - mean” is the average of all B/G and R/G ratios.

- “Shading - max” is the maximum of all B/G and R/G ratios.

The green, yellow and red line circle do not refer to any standard and are only for orientation. They circle around the ideal color ratio of one in 0.05 steps.

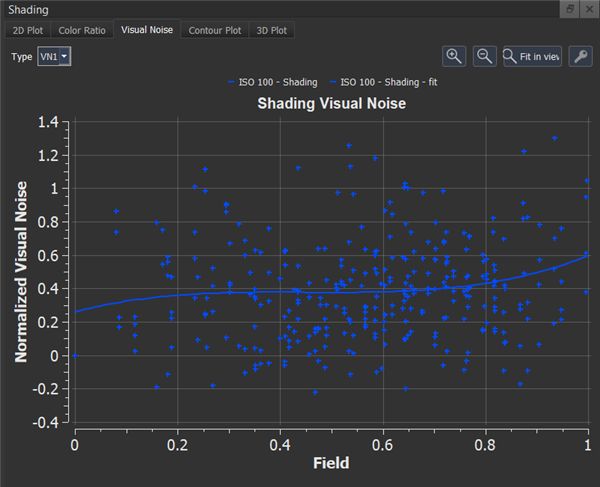

Visual Noise

This plot shows the Visual Noise in the shading ROIs over the field for the viewing conditions which are defined in the analysis settings. You can change the viewing condition by selecting VN1, VN2,…from the dropdown menu.

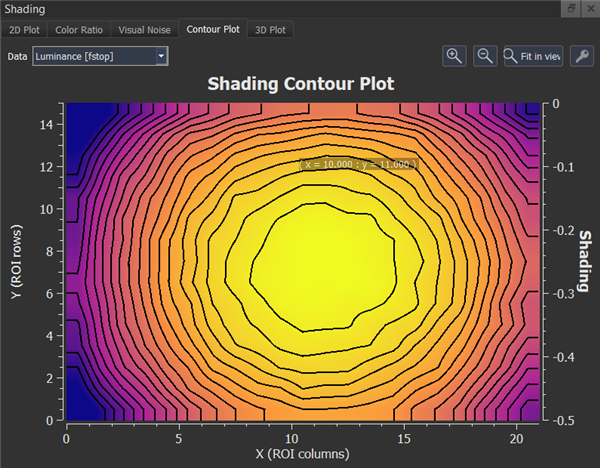

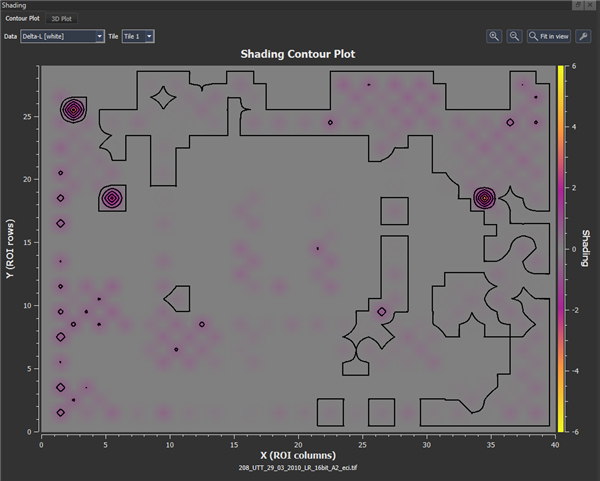

Contour plot

The “Contour” plot shows the uniformity over the columns and rows of the ROIs as an interpolated color-coded image. The contour lines are automatically fitted between the “minimum value” and “maximum value,” these can be changed under “Visualization.” The scaling of the color coding can be changed in the “Visualization” settings.

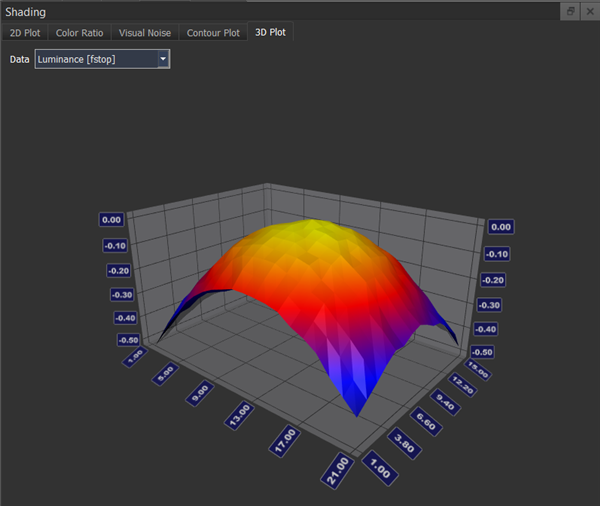

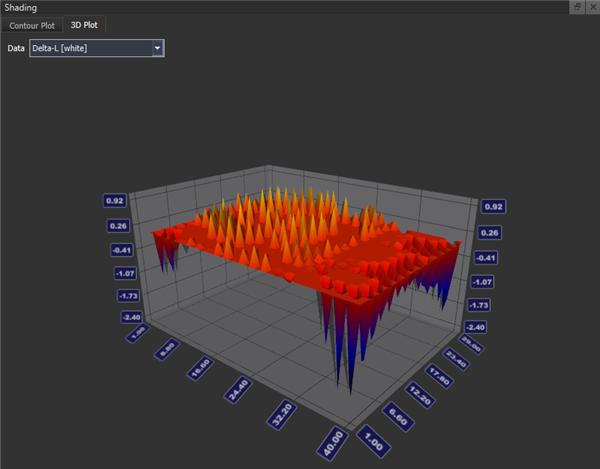

3D Plot

The “3D Plot” shows the uniformity over the columns and rows of the ROIs as an interpolated color-coded 3D rendering. The scaling of the color coding can be changed in the “Visualization” settings. By holding down the right mouse button and dragging, you can change the perspective of the plot.

Numerical Results

Shading(f-stop): The maximum shading of luminance Y in f-stops.

Shading(%): The maximum shading of luminance Y visible in the image. This value is calculated with Y as a weighted sum of R, G, and B, which is not affected by the linearization.

CIE ∆L: The absolute average shading of luminance based on CIE ∆L.

CIE ∆Eab: CIE ∆Eab expresses the maximum color shading over the image field as the maximum color difference. It conforms to the Chrominance Non-Uniformity defined in ISO 17957:2015 and the Color Uniformity defined in IEEE P1858 Standard for Camera Phone Image Quality (CPIQ). In contrast to the ∆E calculation used for color reproduction, the calculation of ∆Eab is done without luminance L*. So you get information only about differences in colors, without luminance.

CIE ∆C: CIE ∆C is the maximum color shading related to a defined reference value.

R/G(DV): The average green and red channel ratio in digital values.

B/G(DV): The average ratio of a blue and green channel in digital values.

Delta SNR(dB): The maximum Delta of SNR over all ROIs.

Delta VN Set1-3: The maximum Delta of Visual Noise overall ROIs.

Distortion

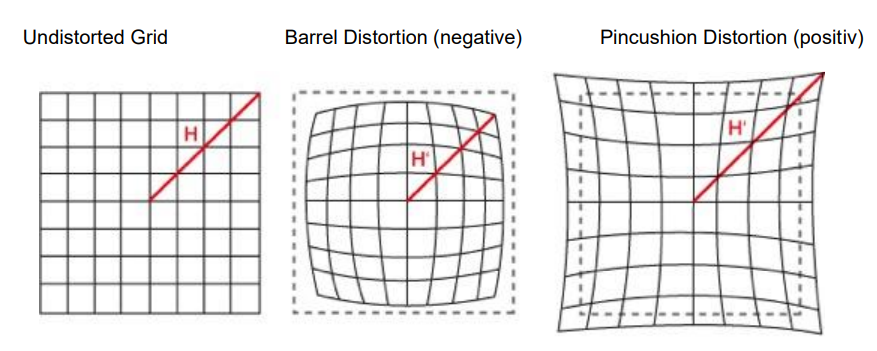

Image distortion occurs when the straight lines of a scene appear to be deformed or curved unnaturally in an image. There are three types of lens distortion called barrel, pincushion, and waveform, also known as mustache distortion. It is important to know that distortion occurs differently depending on the lens system and whether the lens can or cannot be removed from the camera. The iQ-Analyzer-X uses test patterns, crosses, or points distributed over the entire image field with a known position. The center location of the crosses or points is detected with sub-pixel precision and referred to as the target position.

Graphical Results

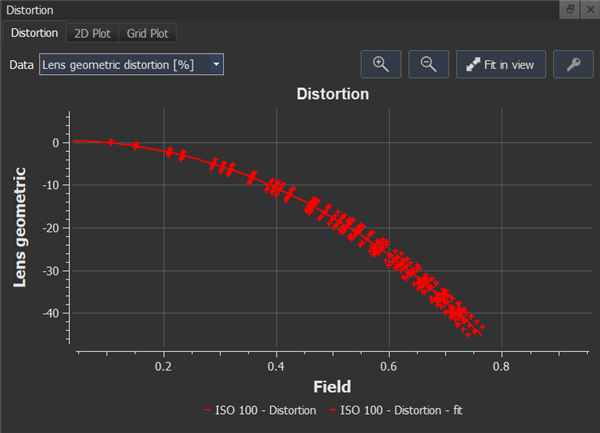

Distortion

The “Distortion” plot shows the Lens Geometric Distortion or Chromatic Aberration over the image field. The image field is the radial distance from the image center to the image corner, mapped from zero to one. A detected point in the corner has a value near one and a detected point in the center near zero.

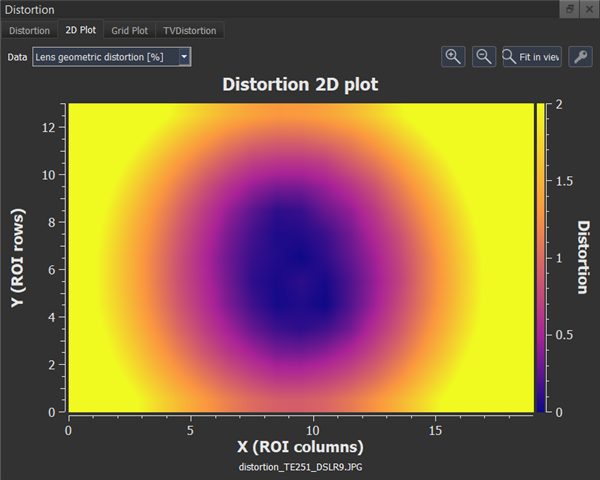

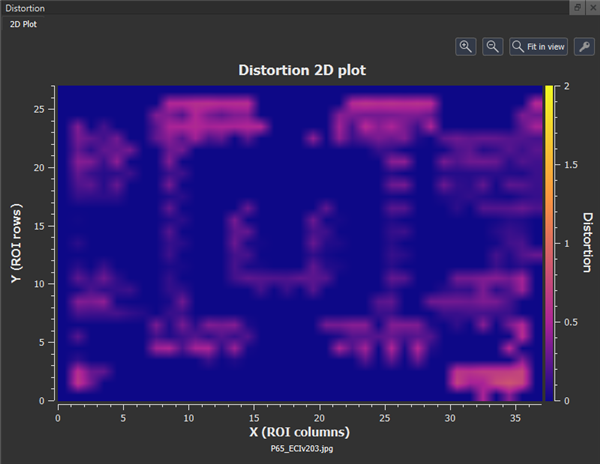

2D Plot

The “2D plot” shows the Lens Geometric Distortion or Chromatic Aberration over the rows and columns of the detected grid, typically crosses, points, or black and white markers. The color shows the intensity of the Lens Geometric Distortion or Chromatic Aberration in percent. The color map is shown on the right side of the graph; adjust its limits in the settings under visualization.

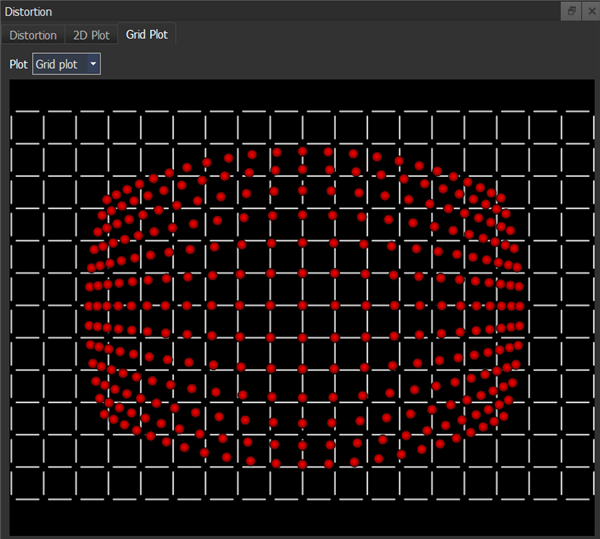

Grid plot

The “Grid plot” shows the detected ROIs as red spheres versus a grid with the expected locations. The farther the sphere is off from its location in the grid, the higher the distortion.

Quiver plot

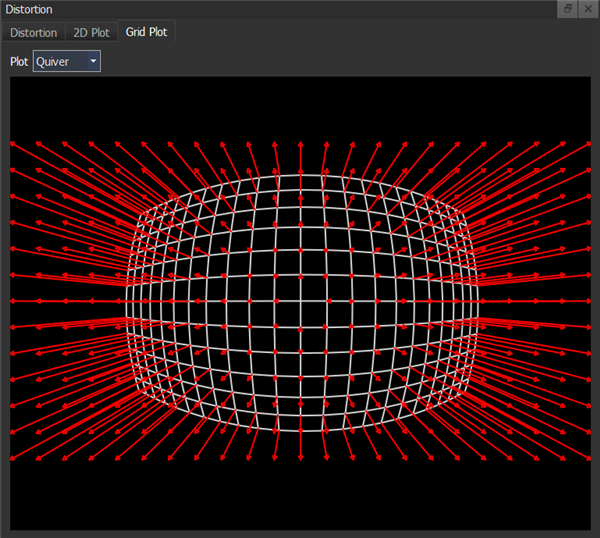

The “Quiver” plot shows the distortion by a vector pointing to its direction.

Note: In the “Quiver” plots, the length of the arrows does not reflect absolute and comparable values but only the directions. The arrows are scaled so that they can be seen clearly, and they only reflect the relative distortion or CA values to each other.

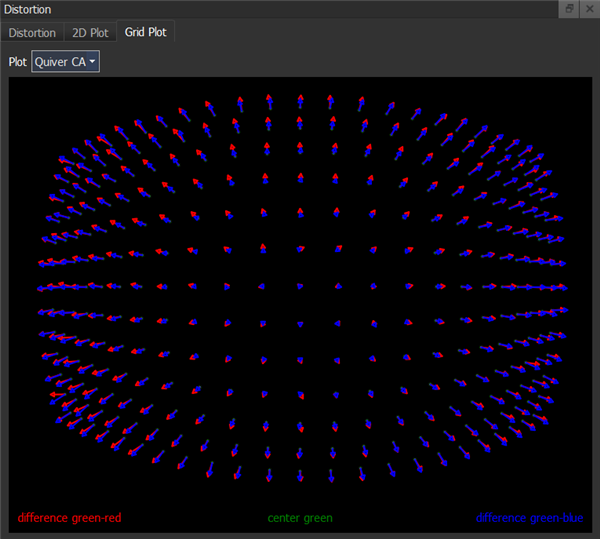

Quiver CA plot

The “Quiver CA” plot also shows vectors for the chromatic aberration of red and blue.

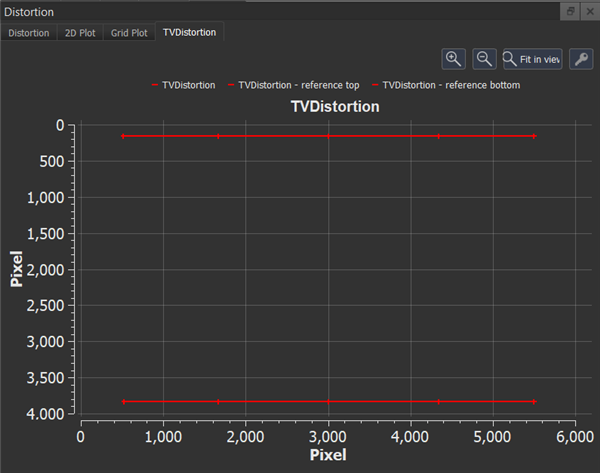

TV Distortion

The “TV Distortion” plot shows the pixel coordinates of the markers used to calculate the TV distortion.

Numerical Results

Line Geometric Distortion (LGD) according to ISO 17850

LGD is defined as below.

Line GD Horizontal:

LineGD h: Line Geometric Distortion in the horizontal direction

A: Maximum height of the line grid pattern of the output image in pixels

B: Minimum height of the line grid pattern of the output image in pixels

V: Number of pixels of the short side of the frame of the output image

i: Suffix presenting each picture height

Line GD Vertical:

LineGD v: Line Geometric Distortion in the vertical direction

α: Maximum width of the line grid pattern of the output image in pixels

β: Minimum width of the line grid pattern of the output image in pixels

V: Number of pixels of the short side of the frame of the output image

i: Suffix presenting each picture width

Line GD Total:

TV Distortion

The results of distortion calculation are shown as EBU-TV-Distortion and SMIA-TV-Distortion (SMIA = Standard Mobile Imaging Architecture). The SMIA definition has been widely adopted in the mobile imaging industry.

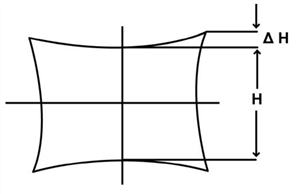

EBU(%): EBU TV distortion is the change of image height from the center to the edge of the image, expressed as a percentage of the actual height in the center.

SMIA(%): SMIA defines distortion as the ratio of the absolute image height at the edges of the image to the image height in the center.

EBU-TV-Distortion and SMIA-TV-Distortion are similar measurements and contain the same information. SMIA-TV-Distortion is always double the EBU-TV-Distortion.

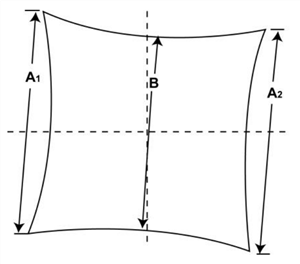

Lens Geometric Distortion (LGD) according to IEEE P1858, similar to Local Geometric Distortion in ISO 17850

LGD is defined as:

H' = Actual dot distance from the center of the image

H = Expected dot position

The geometric distortion for a grid position is the delta between the radial distance of the actual grid position H' and the radial distance to the ideal grid position H, divided by the ideal grid position H.

For each detected point in the grid, the LGD is calculated.

H'< H indicates negative distortion → barrel distortion.

H'> H indicates positive distortion → pincushion distortion.

LGD mean: The average geometric lens distortion of all grid positions.

LGD worst: The maximum LGD of all grid positions.

LGD worst(fit): The worst LGD value fitted to a polynomial, which degree is defined in the “Distortion” settings.

Chromatic Aberration (CA)

CA G/R mean: The average pixel distance between the green and red channels.

CA G/R max: The mean value of the ten largest distances between green and red.

CA G/B mean: The average pixel distance between the green and blue channels.

CA G/B max: The mean value of the ten largest distances between green and blue.

LCD G/R [pix]: Lateral Chromatic Displacement in pixels between the green and red channel according to CPIQ. The distance between green and red channel is calculated based on polar coordinates. For the LCD G/R the maximum values for green and red channel are used.

LCD G/R [%]: Lateral Chromatic Displacement in percent of the picture height between the green and red channel according to CPIQ. The LCD G/R in pixels is set in relation to the image height in pixels.

LCD G/B [pix]: Lateral Chromatic Displacement in pixels between the green and red channel according to CPIQ. The distance between green and blue channel is calculated based on polar coordinates. For the LCD G/R the maximum values for green and red channel are used.

LCD G/B [%]: Lateral Chromatic Displacement in percent of the picture height between the green and red channel according to CPIQ. The LCD G/B in pixels is set in relation to the image height in pixels.

—-

Longitudinal Chromatic Aberration (LCA)

LCA Total: Mean value of the longitudinal chromatic aberration.

LCA Horizontal: Longitudinal chromatic aberration in the horizontal direction measured on the center cross (horizontal line of the cross).

LCA Vertical: Longitudinal chromatic aberration in the vertical direction measured on the center cross (the vertical line of the cross).

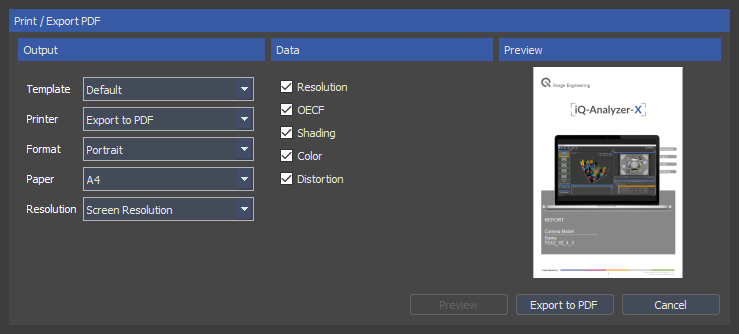

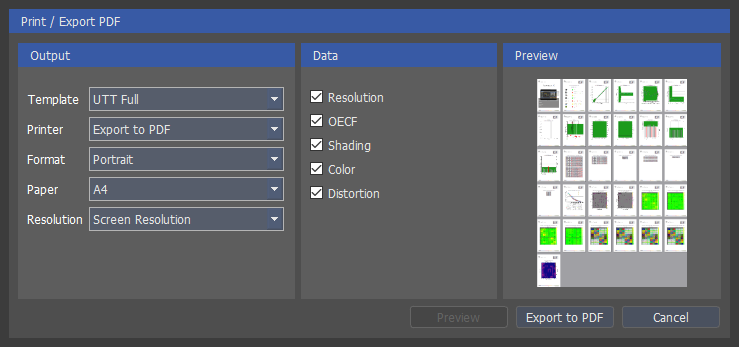

Export Results

The results can be exported as a *.xml or *.pdf file from the “File” menu. In the *.xml file, all numerical results will be saved. You can use this file to create your custom report. The *.pdf export provides basic layout adjustments and an option for which measurements will be included.

In the “General” tab under “Configuration” a custom logo and your company name can be inserted to appear in the .pdf report.

In the “PDF Settings” tab under “Configuration” you can define, which metadata and settings are added to the report.

The generated report shows only the image(s), which are selected in the “Input dock”.

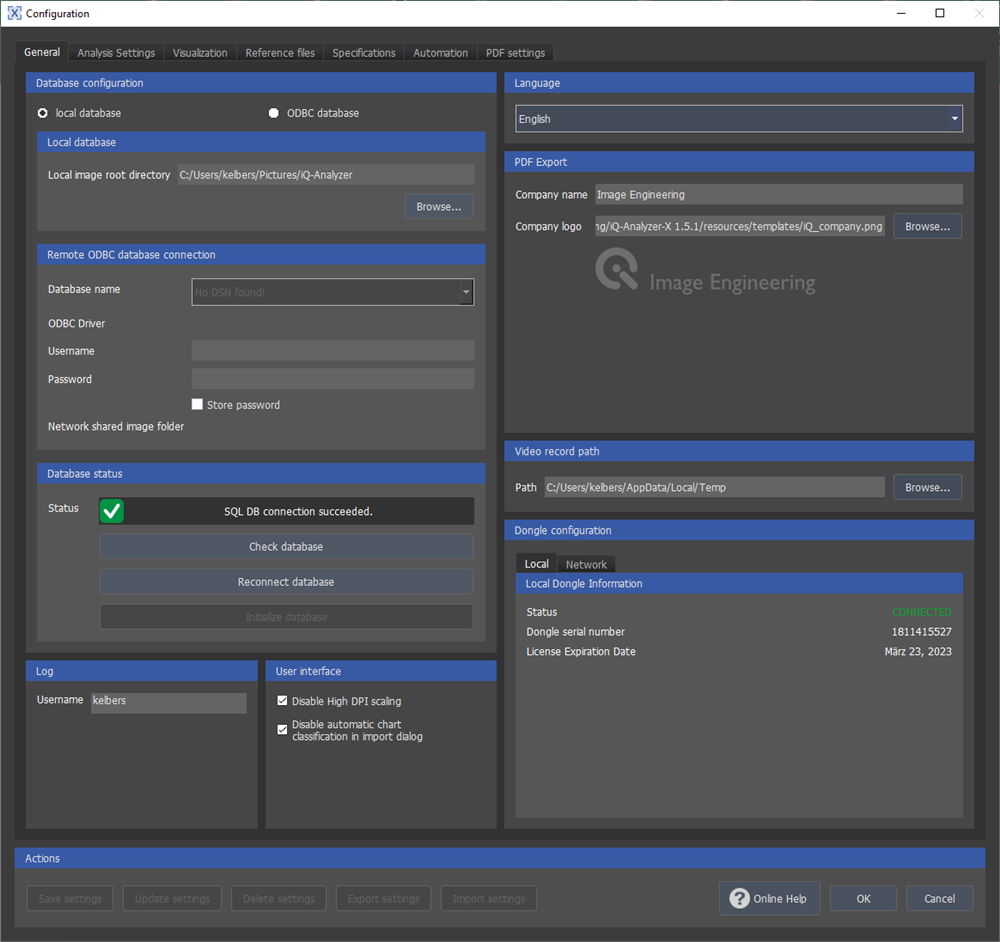

Configure

General

Database configuration

Select the database where you want to store your data. You can work with a local or remote database and switch between them.

Local image root directory

This is the path where the images of your analysis are stored. You can choose a different folder by clicking “Browse…”.

Remote ODBC database connection

Provide the required data to connect to your remote ODBC database.

Database status

You can check the database status and reconnect it in case of any changes.

User Interface

“Disable automatic chart classification in import dialog”- By activating this checkbox, you can prevent iQ-Analyzer-X from trying to find a suitable chart layout. It makes sense to activate this checkbox if you are working with custom charts that are not known to iQ-Analyzer, or if the recognition leads to a chart that has to be specified by the user anyway, such as the TE269V2.

Language

Set your preferred language here.

PDF Export

Set your company name and logo and include them in your exported *.pdf reports.

Log

Set the username that will appear in the log.

Dongle Configuration

Displays information about the local or network dongle currently in use.

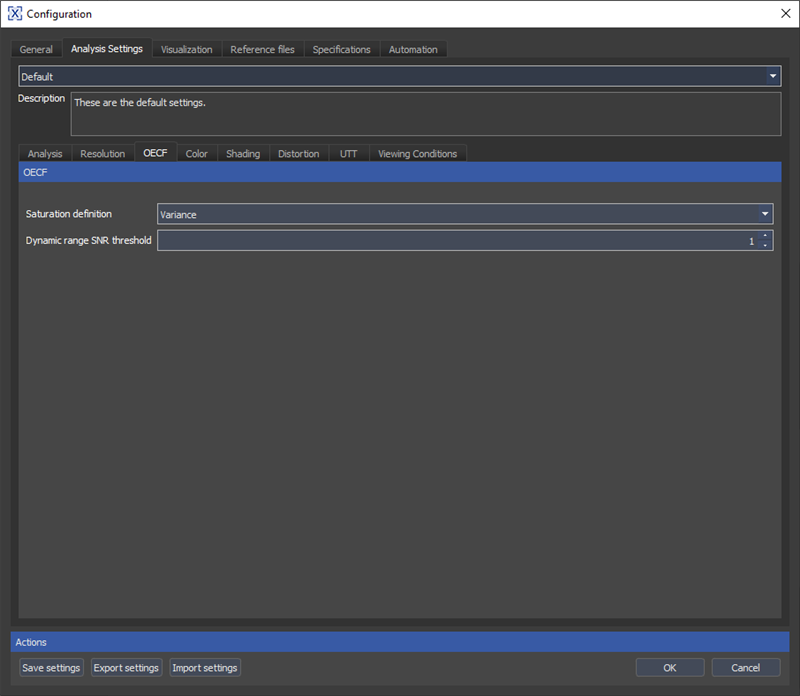

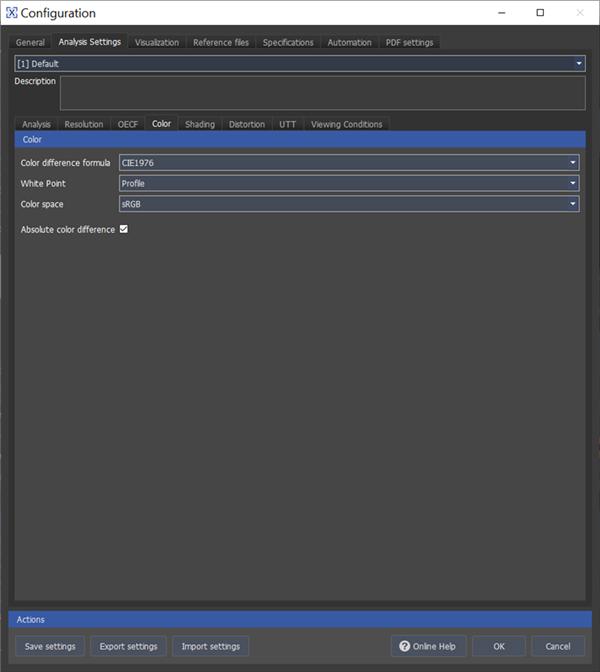

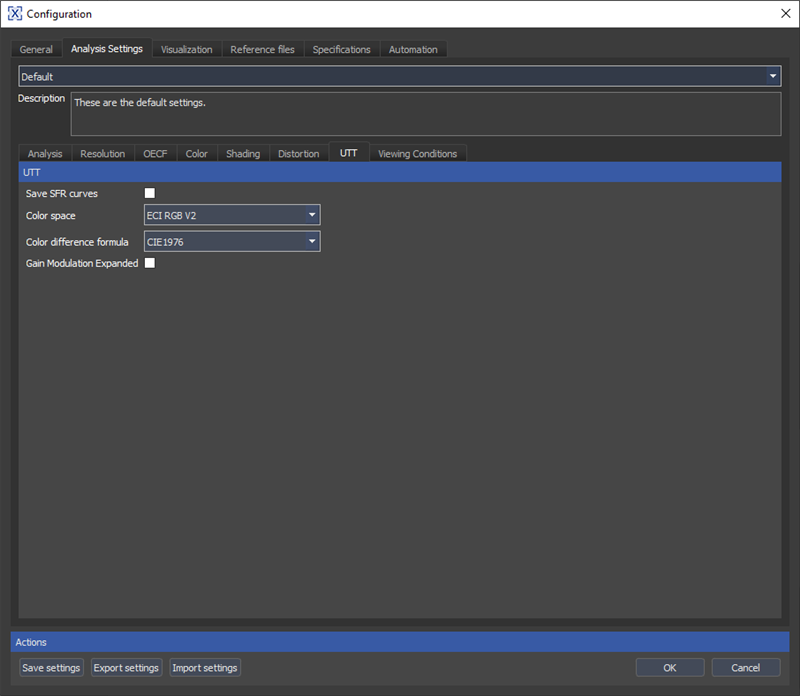

Analysis Settings

In the “Analysis Settings” menu, you can define the measurements and parameters for your image analysis. The settings can be saved to the database to make a repeating application easy. To apply the settings to your analysis, you need to select them in advance in the input dock.

Note that you can also update your settings with new values. When you do this, the “ID” number of your settings will change. The old settings are still in the database under the old ID in case they were used for a previous analysis. This is important to know if you work with CLI scripts. You may need to change the IDs in your script as well.

Analysis tab

In this tab, you can define the measurements carried out when you start an analysis. Please note that some measurements might not be available, depending on your chart. To apply your settings you need to save them first. The right column only applies to UTT charts.

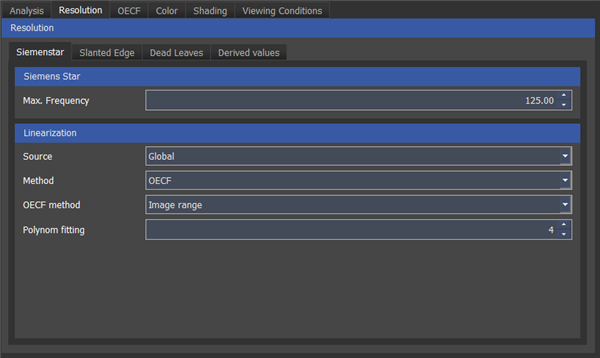

Resolution tab

Three different methods for measuring resolution can be applied with iQ-Analyzer-X - Siemens star, slanted edge, and dead leaves. All of the methods have the same options for linearization.

Source: Depending on your chart, you can choose between local, global, and no linearization.

- Local: The gray patches close to your measurement target are used. Example: In the TE268 (25 Siemens stars), each star is linearized with the local gray patches around each star.

- Global: A single set of gray patches is used for linearization. For example, in a TE42V2 or the TE268 target, the OECF patches in the center are used.

Method:

- Profile: If you choose “Profile,” the image will be linearized based on the color space of your image (e.g., sRGB).

- The “OECF” setting takes the measured OECF into account.

OECF method:

- Data range: The entire data range is used for the calculation (e.g., 0…255 for 8bit images)

- Image range: The gray patches' minimum and maximum digital value is used.

- Normalized image range: If black and white reference patches are available, these are used to normalize the modulation.

- MTF: An older approach where the black value is subtracted from the image to achieve a de-facto normalization.

See this paper for details: https://www.image-engineering.de/library/conference-papers/862-linearization-and-normalization-in-spatial-frequency-response-measurement

Polynomial fitting: Defines the degree of the polynomial fitting curve for the OECF.

Siemens Star

Maximum frequency: You can choose what frequency iQ-Analyzer-X calculates the modulation. The value is provided as a percentage of the Nyquist frequency. So if the Nyquist frequency is 1000 LP/PH and you set the maximum frequency to 125%, iQ-Analyzer-X will analyze the radii that equal frequencies lower than 1250 LP/PH. The edge of the Siemens star defines the lower frequency limit.

Slanted Edge

- Polynomial fitting: The degree of polynomial fit for linearization can be adjusted.

- Max. Frequency: See Siemens star.

- Edge Profile Source: You can choose between original or linearized data.

- Color Channel: You can choose if the SFR for RGBY or only Y should be measured.

Dead Leaves

Analysis Method: You can choose between three different calculation methods for Dead Leaves - Core, Direct, and Cross. Cross is the recommended method as it is robust against noise's impact. Please refer to this paper on our website for more detailed information about the differences.

Derived values

Here you can specify the parameters you want to show in the results. These are values that are calculated based on an SFR.

OECF tab

Saturation definition

Variance: Saturation calculation is based on the variance of the DVs.

Dynamic range SNR threshold

The dynamic range is the difference between the illumination needed to reach saturation and the minimum illumination defined by a specified SNR value. The standard value for ISO 15739 is SNR = 1. This value may lead to problems due to signal processing and noise reduction, as an SNR of 1 is never reached, and thus, the threshold might be increased. We have good experience using a threshold of three, and a threshold change should be reported if deviating from the ISO standard.

Color tab

Color difference formula

The iQ-Analyzer-X calculates Delta E from two Lab data sets, the reference, and the image sample set. You can choose between CIE1976, CIE1994, CIE2000 and CIE2000 SL1 formula for calculating Delta E, with the most common being CIE1976. A more detailed description of the details is in the “Results” section.

White Point

Currently, the only option is to take the white point from the image profile.

Color space

If the test image contains a color profile, the profile is automatically applied, otherwise the color space selected here is used.

Absolute color difference

Activate this check box if you want to get results with absolute values. Absolute values only represent the number of color differences but not the direction.

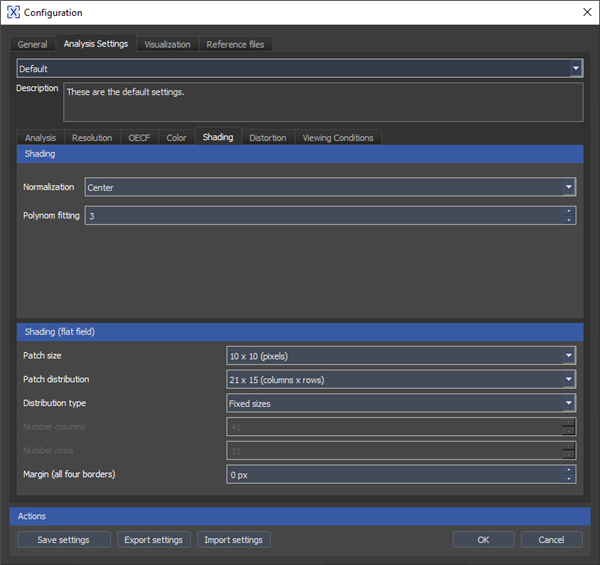

Shading tab

Normalization

“Brightest” sets the coordinates with the maximum luminance as a reference for normalization (reference = max. luminance = 0). This option makes sense if your brightest patch shows an offset to the image center due to misalignment of the lens to the sensor. “Center” applies to the center of the image for normalization (reference = center = 0).

Polynom fitting

“Polynom fitting” defines the polynomial degree that is fitted to the data.

Patch Size

“Patch Size” defines the size of the shading ROIs in pixels.

Patch distribution

“Patch distribution” defines the number of columns and rows of the shading measurements.

Distribution type

“Fixed Sizes” takes the “Patch Size” and the “Patch Distribution” value to generate the grid with the shading ROIs. “Seamless” creates a grid that leaves no empty spaces between the shading ROIs.

- “Number columns” defines the number of columns of the seamless grid.

- “Number rows” defines the number of rows of the seamless grid.

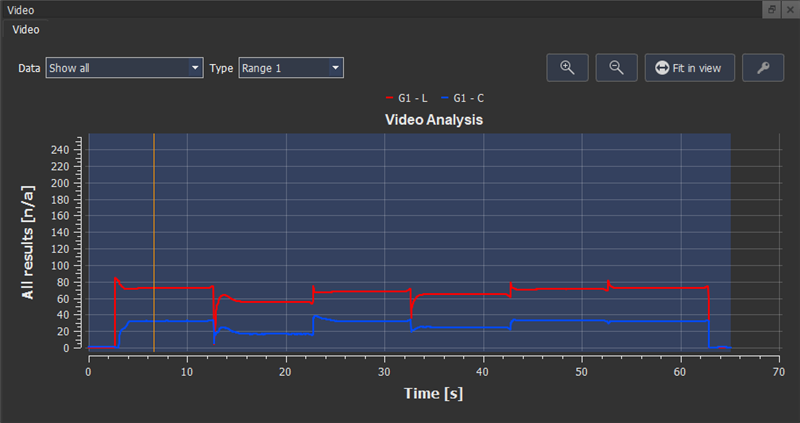

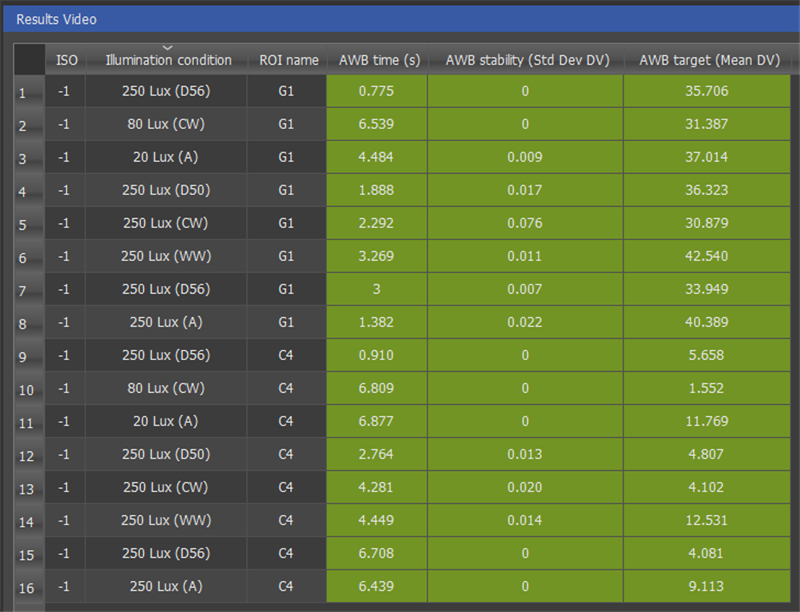

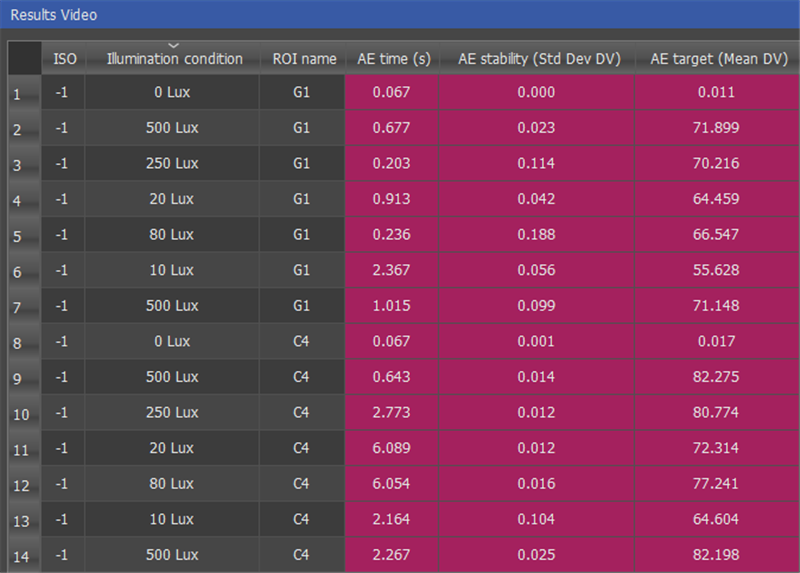

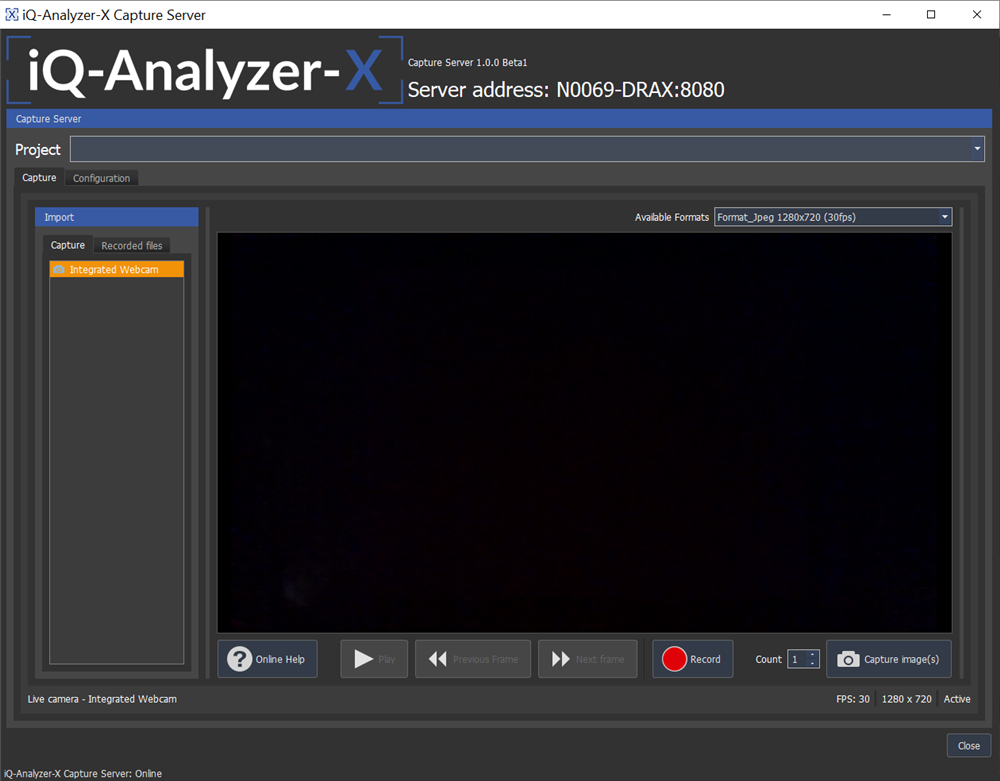

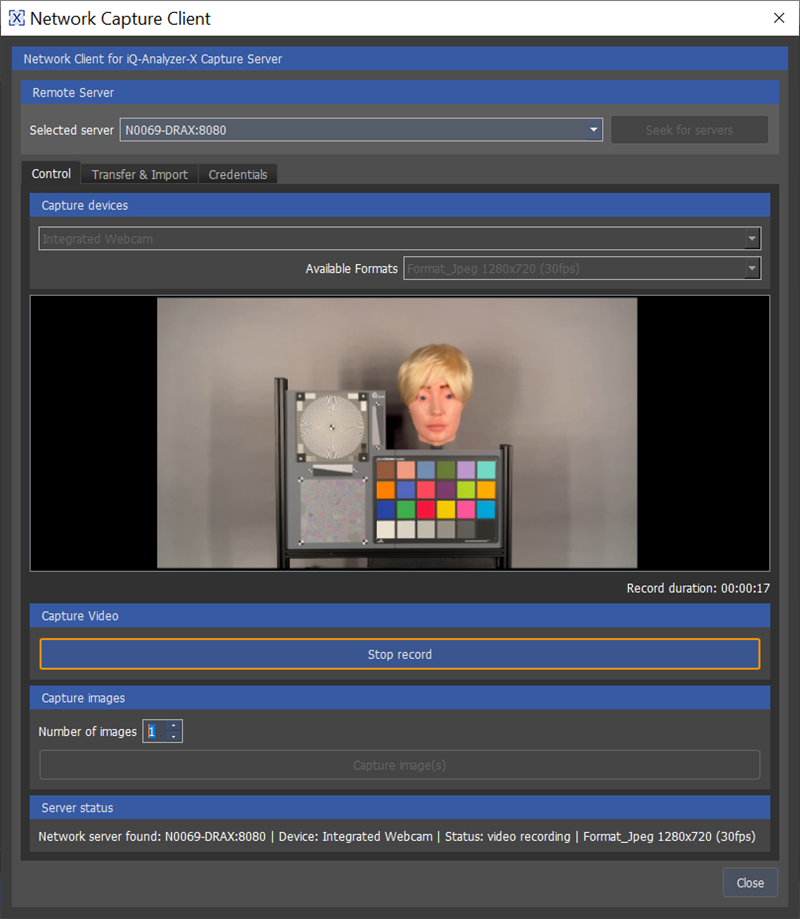

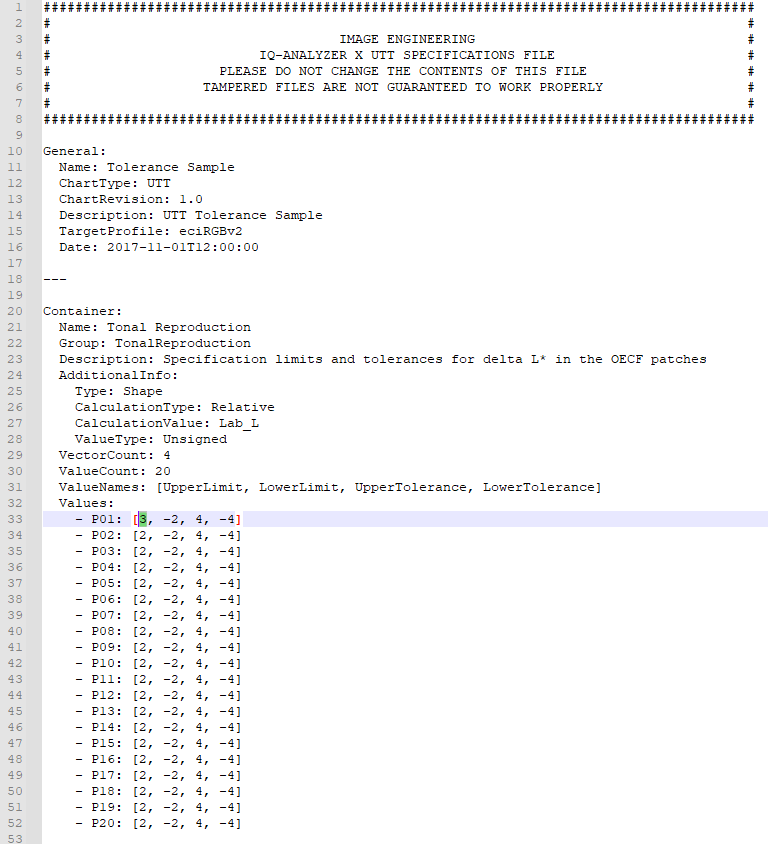

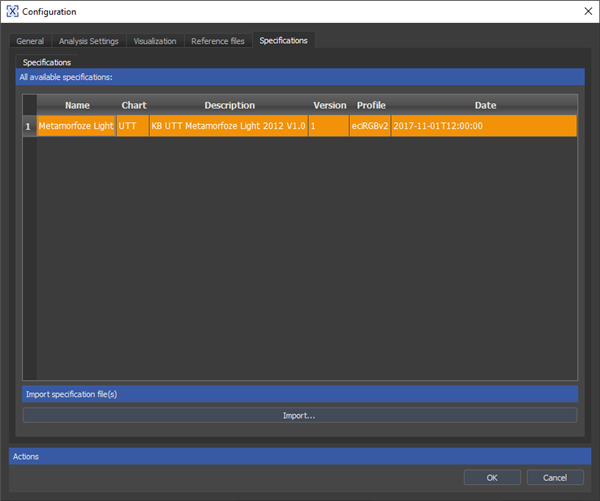

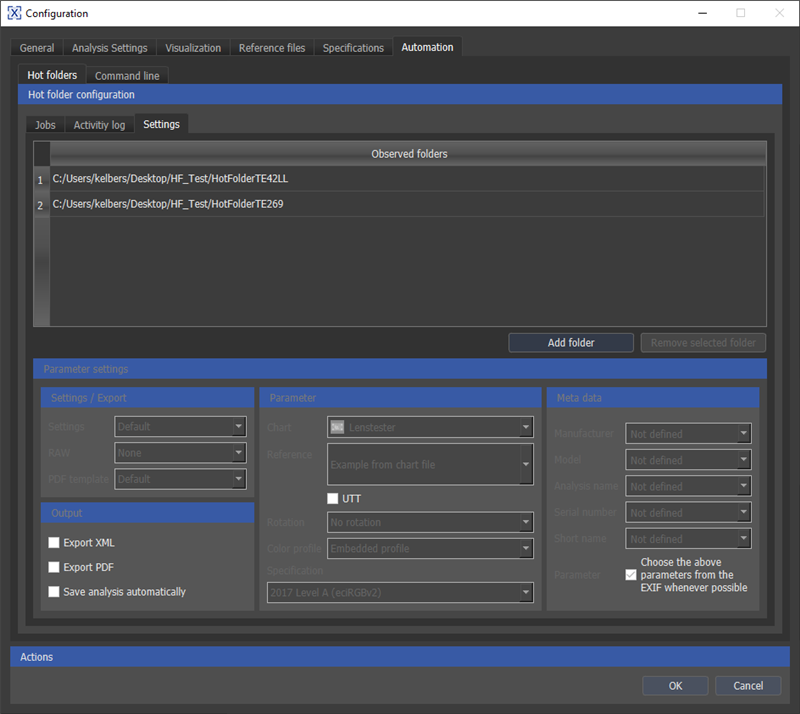

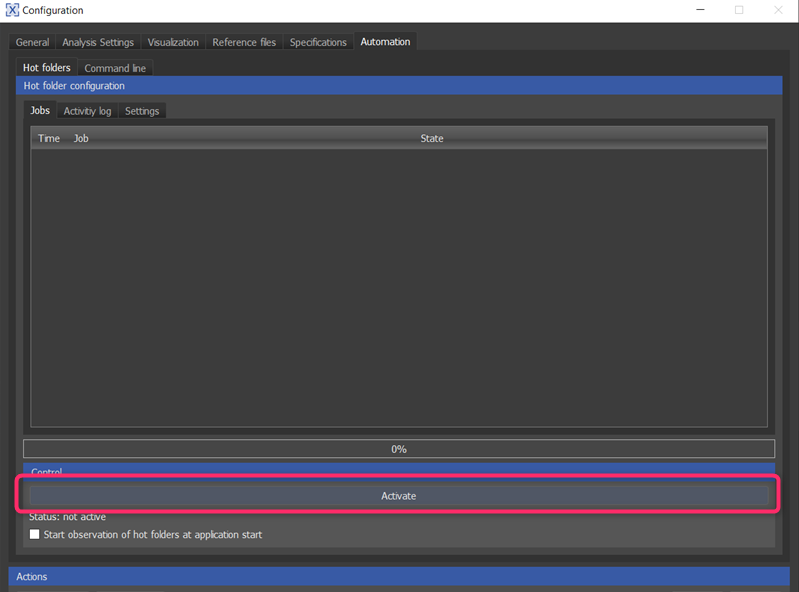

Margin (all four borders)